Introduction to Polyethylene Pyrolysis (PEP) Material

Yêu cầu báo giá

Nếu bạn có bất kỳ câu hỏi nào về sản phẩm và dịch vụ của chúng tôi, vui lòng để lại tin nhắn cho chúng tôi

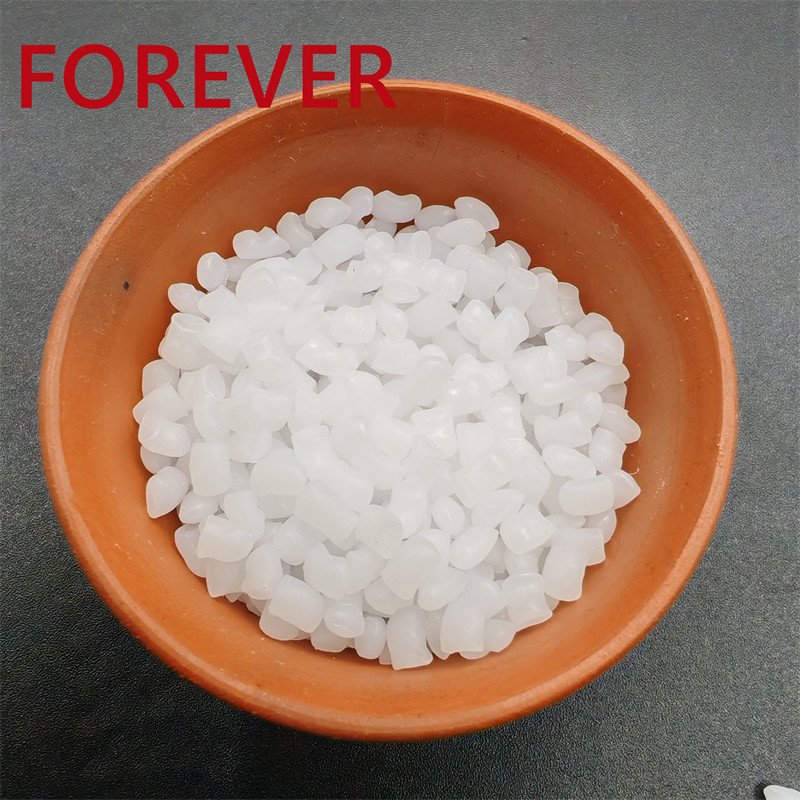

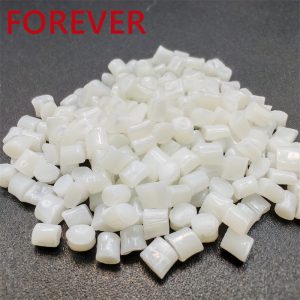

**Introduction to Polyethylene Pyrolysis (PEP) Material**

In the ever-evolving world of materials science, Polyethylene Pyrolysis (PEP) has emerged as a groundbreaking innovation, capturing the attention of industries and researchers alike. PEP is not just another material; it’s a testament to human ingenuity and our relentless pursuit of sustainable solutions. Let’s dive into the fascinating world of PEP and explore its unique characteristics, applications, and the promise it holds for the future.

**What is PEP?**

Polyethylene Pyrolysis, or PEP, is a advanced material derived from the thermal decomposition of polyethylene, one of the most widely used plastics in the world. Through a controlled pyrolysis process, polyethylene is broken down into its fundamental components, which are then reconstituted into a high-performance material with enhanced properties. This process not only recycles plastic waste but also transforms it into a valuable resource, aligning perfectly with the principles of a circular economy.

**The Magic Behind PEP**

The transformation of polyethylene into PEP is nothing short of magical. Imagine taking something as mundane as a plastic bag and turning it into a material that rivals the strength of metals, the flexibility of rubber, and the durability of ceramics. The pyrolysis process involves heating polyethylene in the absence of oxygen, causing it to decompose into smaller molecules. These molecules are then carefully reassembled to create PEP, a material that boasts an impressive array of properties.

**Properties That Set PEP Apart**

1. **Exceptional Strength and Durability**: PEP exhibits remarkable tensile strength and resistance to wear and tear, making it ideal for applications that demand longevity and reliability.

2. **Lightweight**: Despite its strength, PEP is incredibly lightweight, offering a superior strength-to-weight ratio that is highly sought after in industries such as aerospace and automotive.

3. **Thermal Stability**: PEP can withstand extreme temperatures, both high and low, without losing its structural integrity. This makes it suitable for use in harsh environments.

4. **Chemical Resistance**: PEP is highly resistant to a wide range of chemicals, ensuring its performance remains uncompromised in corrosive environments.

5. **Eco-Friendly**: By utilizing plastic waste as its raw material, PEP contributes to reducing the environmental impact of plastic pollution. It’s a material that not only performs but also protects our

Câu hỏi thường gặp

Có, chúng tôi hoan nghênh đơn đặt hàng mẫu để thử nghiệm và kiểm tra chất lượng. Các mẫu hỗn hợp cũng được chấp nhận.

Mẫu cần 3-5 ngày, thời gian sản xuất hàng loạt cần 1-2 tuần đối với số lượng đặt hàng nhiều hơn.

MOQ thấp, có sẵn 1 cái để kiểm tra mẫu

Có, chúng tôi cung cấp bảo hành 1 năm cho sản phẩm của mình. Sau thời gian bảo hành, chúng tôi có thể tiếp tục cung cấp dịch vụ sau bán hàng cho sản phẩm và thay thế phụ tùng thay thế.