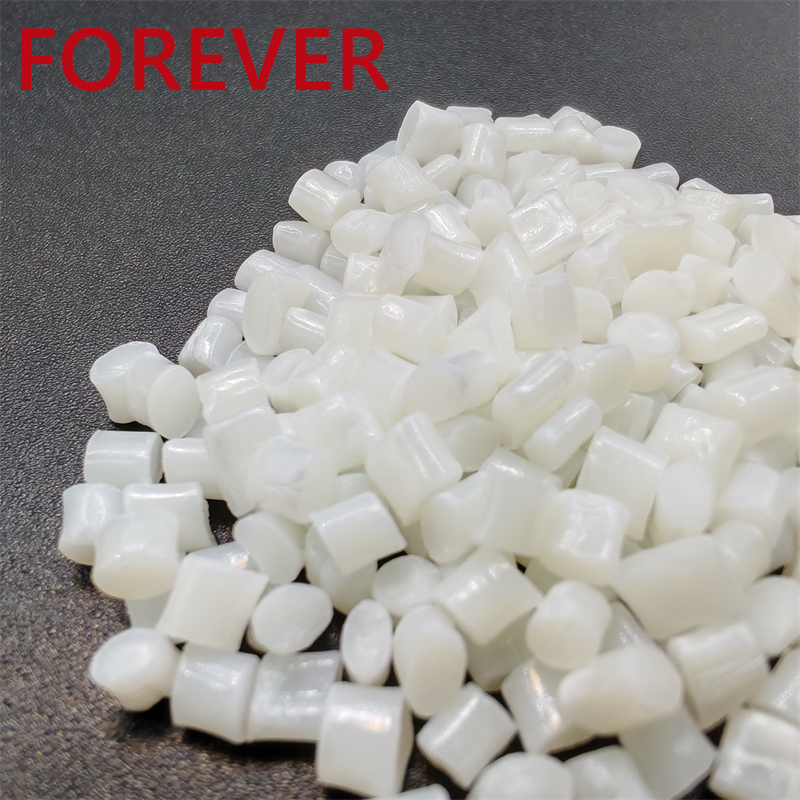

Polymer PRC100 is a remarkable synthetic polymer renowned for its unique combination of properties, making it a preferred choice across a wide range of industries.

Physical and Chemical Properties

PRC100 typically exhibits a high – density structure, which endows it with excellent mechanical strength. This high density contributes to its remarkable hardness and stiffness, enabling it to maintain its shape under significant stress. It also has a relatively high melting point, allowing for processing at elevated temperatures without significant degradation. Chemically, PRC100 offers good chemical resistance. It can withstand exposure to various chemicals, including many acids, alkalis, and organic solvents. This property makes it suitable for applications where contact with potentially corrosive substances is likely.

Processing Characteristics

The processing of Polymer PRC100 is facilitated by its well – behaved melt flow properties. During manufacturing processes such as injection molding, extrusion, and blow molding, it can flow smoothly through dies and molds. This smooth flow ensures the production of high – quality products with consistent dimensions and surface finishes. Manufacturers can achieve high production rates while maintaining product integrity, reducing production costs in the long run.

Applications

In the automotive industry, PRC100 is used to manufacture various components, such as engine parts, due to its heat resistance and mechanical strength. In the construction sector, it is employed in the production of pipes and fittings, where its chemical resistance and durability are highly valued. The packaging industry also benefits from PRC100, using it to create rigid containers for storing chemicals and other products that require protection from chemical reactions and mechanical damage.