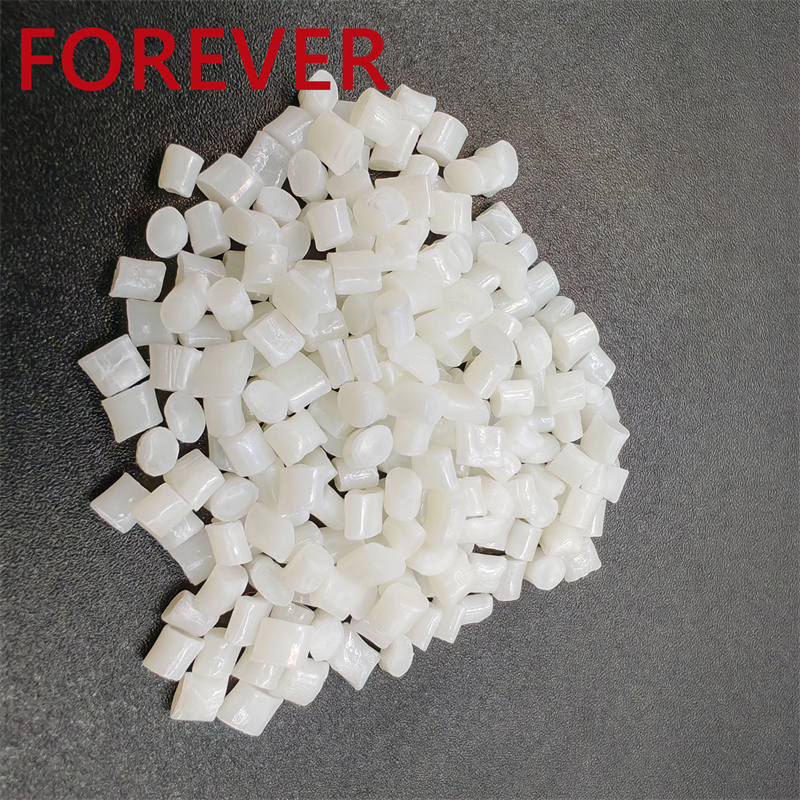

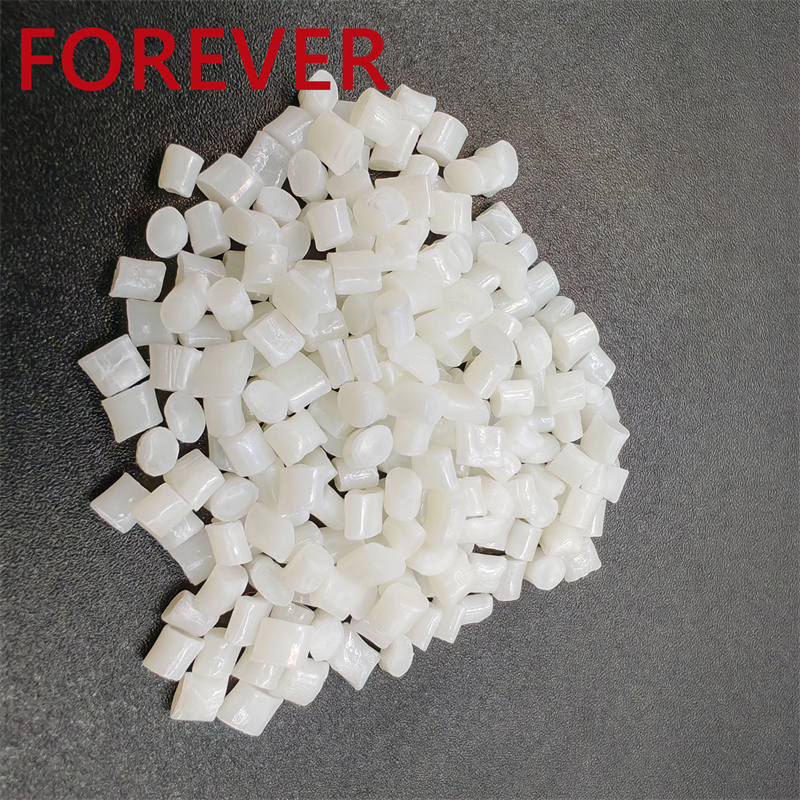

Xangai Petroquímica LDPE PP

Solicitar um orçamento

Se você tiver alguma dúvida sobre nossos produtos e serviços, sinta-se à vontade para nos deixar uma mensagem

Low density polyethylene (LDPE):

N150: Anti -chemical blowing high -pressure average polyethylene, suitable for agricultural film, etc. It has good anti -chemical and machining performance, and can be used for blow molding and extrusion.

ZJ2600: It can be used for plastic spraying and plastic. It is a low -density polyethylene plastic.

LF2700: The level of low -density polyethylene is applied to the coating process, such as the manufacturing of products such as car pads, fake flowers and plants.

Q400: Squeezing and blowing -blown anti -chemical packaging thin -film raw materials have good anti -chemical properties and are suitable for film production.

N210: Low -density polyethylene of film -blowing, blowing plastic, and optical grade can be used to produce various types of film.

Q210: Film -grade low -density polyethylene, which is antimedies and is suitable for packaging film.

Q281, Q281D: It can be used to pack the film’s extrusion and blow molding process.

Polypropylene (PP):

GM750E: injection molding, blowing plastic, brushed medical -grade general -level plastic raw materials, has a variety of characteristic levels, such as transparent levels, high temperature resistance, high gloss, high rigidity, enhanced, flame retardant levels, etc., which can be used in various fields.

M800E, F800E: High -transparent food -grade medical high -luster plastic particles, suitable for food packaging and medical fields.

M4550E: Injection polypropylene can be used for drawing, which has medical grade, food grade and other purposes.

T300: Injection polypropylene has the characteristics of high strength and squeezing brushed heat resistance.

M800EX, M3000R, GM250E: injection molding flame retardant high -glossy food -grade polypropylene is suitable for food grades, medical grades, electronic electronic components and other fields required for flame retardant performance.

Perguntas frequentes

Sim, aceitamos pedidos de amostra para testar e verificar a qualidade. Amostras mistas são aceitáveis.

A amostra precisa de 3 a 5 dias, o tempo de produção em massa precisa de 1 a 2 semanas para quantidades pedidas maiores.

MOQ baixo, 1pc para verificação de amostra está disponível

Sim, oferecemos 1 ano de garantia para nossos produtos. Após o período de garantia, podemos continuar a fornecer serviço pós-venda de produtos e substituição de peças de reposição