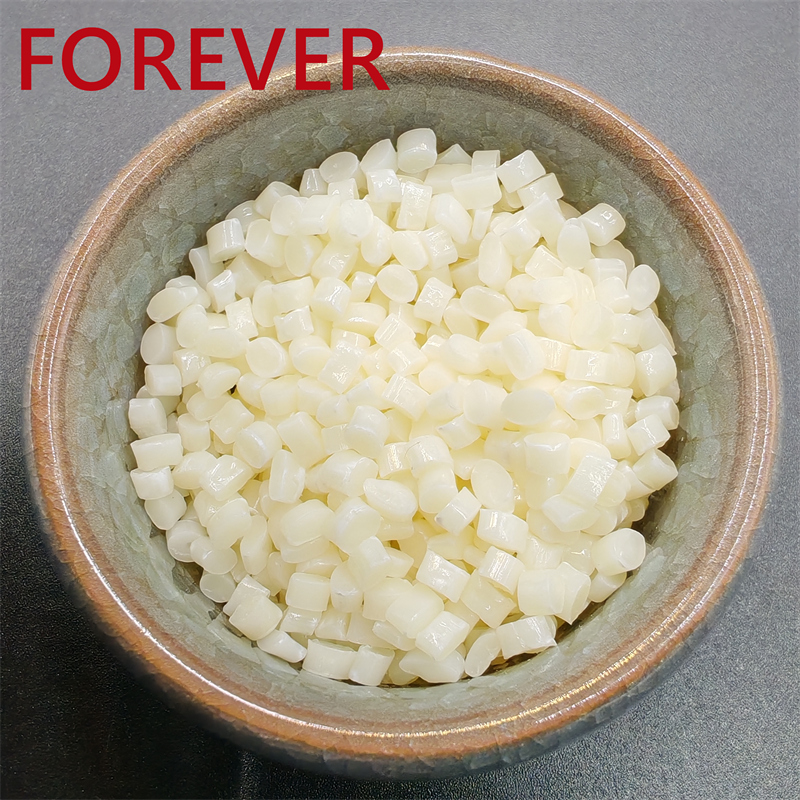

Polypropylene products thin -walled plastic grade MM90, MM70X

Solicitar um orçamento

Se você tiver alguma dúvida sobre nossos produtos e serviços, sinta-se à vontade para nos deixar uma mensagem

Polypropylene products thin -walled injection class MM90 and MM70X are mainly used to make thin -walled products.

:Mm90:

Uses: It is especially suitable for the manufacture of daily necessities such as plastic barrels, plastic cups.

Features: It has the characteristics of high transparency, heat resistance, and high flow.

:Mm70x 7:

Uses: As a thin wall injection plastic, it is widely used in the production of various thin -walled products.

Features: By adding sorgeol -type compounds, you can maintain less sorbitol -type compounds under high temperature and thin walls. At the same time, you can reduce the fog of polypropylene wall injection plastic, so that thin wall injection products have good mechanical properties, heat, heat Performance and optical properties (this characteristic may also be applied to MM90, because the two belong to thin -walled injection levels).

In summary, the polypropylene product thin -walled plastic MM90 and MM70X occupy an important position in the plastic product industry due to its unique performance and extensive use.

What information do you also want to know about polypropylene products in thin -walled plastic MM90 and MM70X? For example, market price, production process, etc.

Perguntas frequentes

Sim, aceitamos pedidos de amostra para testar e verificar a qualidade. Amostras mistas são aceitáveis.

A amostra precisa de 3 a 5 dias, o tempo de produção em massa precisa de 1 a 2 semanas para quantidades pedidas maiores.

MOQ baixo, 1pc para verificação de amostra está disponível

Sim, oferecemos 1 ano de garantia para nossos produtos. Após o período de garantia, podemos continuar a fornecer serviço pós-venda de produtos e substituição de peças de reposição