What are the characteristics and applications of Sinopec’s polypropylene resins? 2

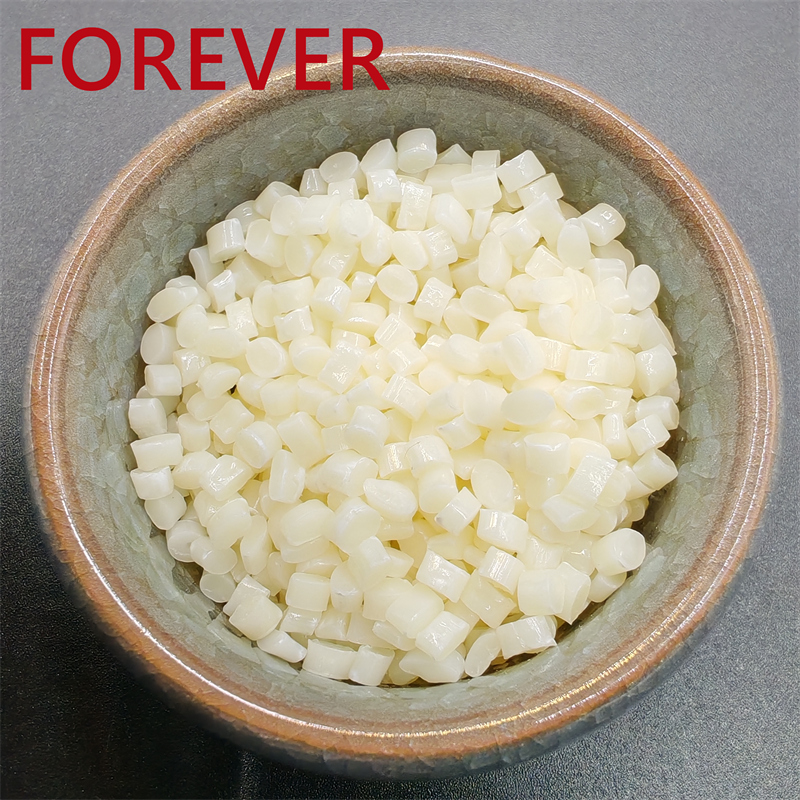

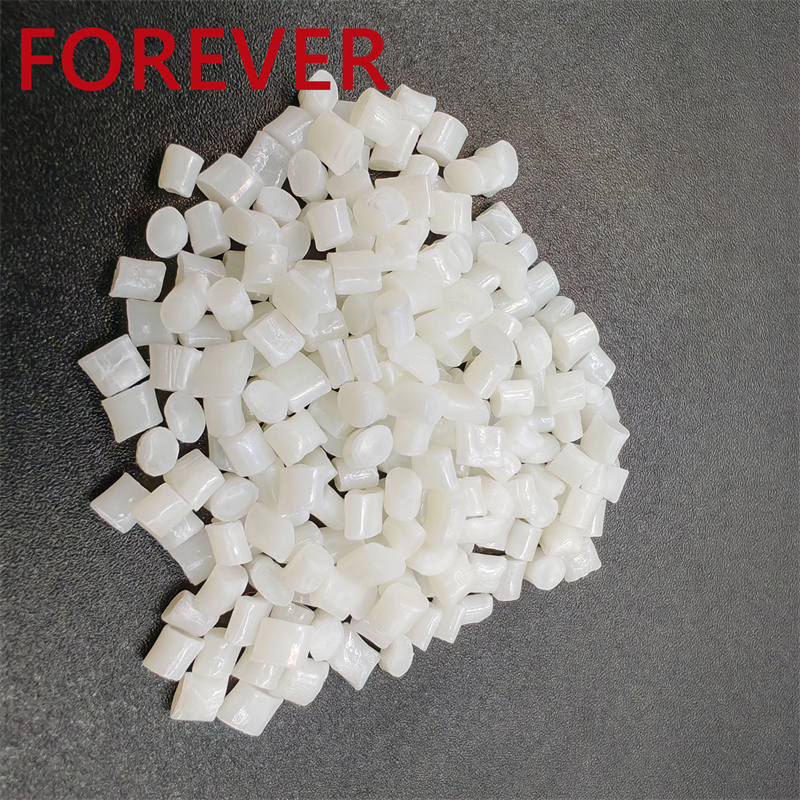

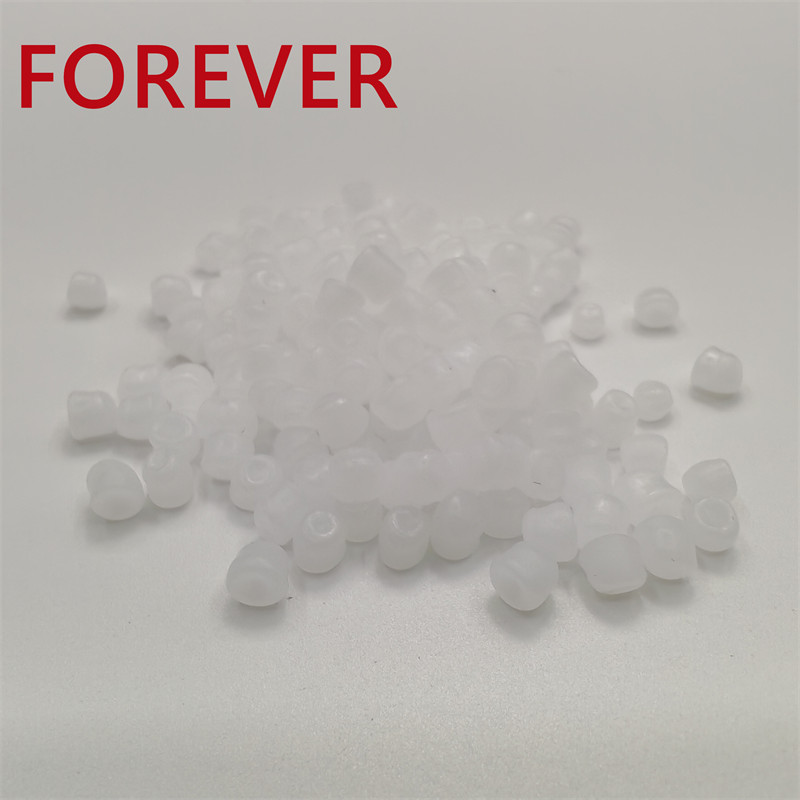

Packaging Industry: Food Packaging:Sinopec’s polypropylene resins are widely used in food packaging due to their excellent barrier properties against moisture, gases, and odors, which help to preserve the freshness and quality of food products. They are used to produce various packaging forms such as plastic bags, containers, and food packaging…

Categories:

Tags:

Appliances, Automotive, Cabling, Fibers, Filaments, Food Packaging, Housings, Non-food packaging, Non-woven, Textile, Wiring

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts