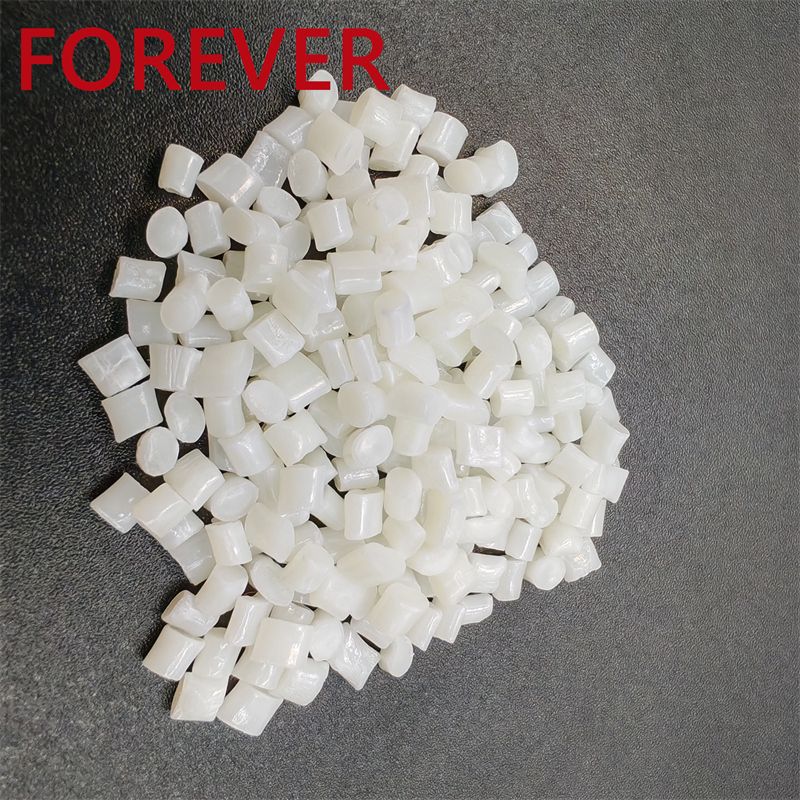

Polyethylene GA450

Polyethylene GA450: A Versatile and High – Performance Polymer Polyethylene GA450 is a remarkable polyethylene grade renowned for its unique combination of properties that make it highly sought-after in various industries. 1. Physical PropertiesGA450 typically exhibits a medium – density range. This density level contributes to its well –…

Categories:

Tags:

bending and shaping without cracking, good balance between stiffness and flexibility, high -performance, medium-density, Polymer, well - balanced physical characteristics

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

Polyethylene GA450: A Versatile and High – Performance Polymer

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts