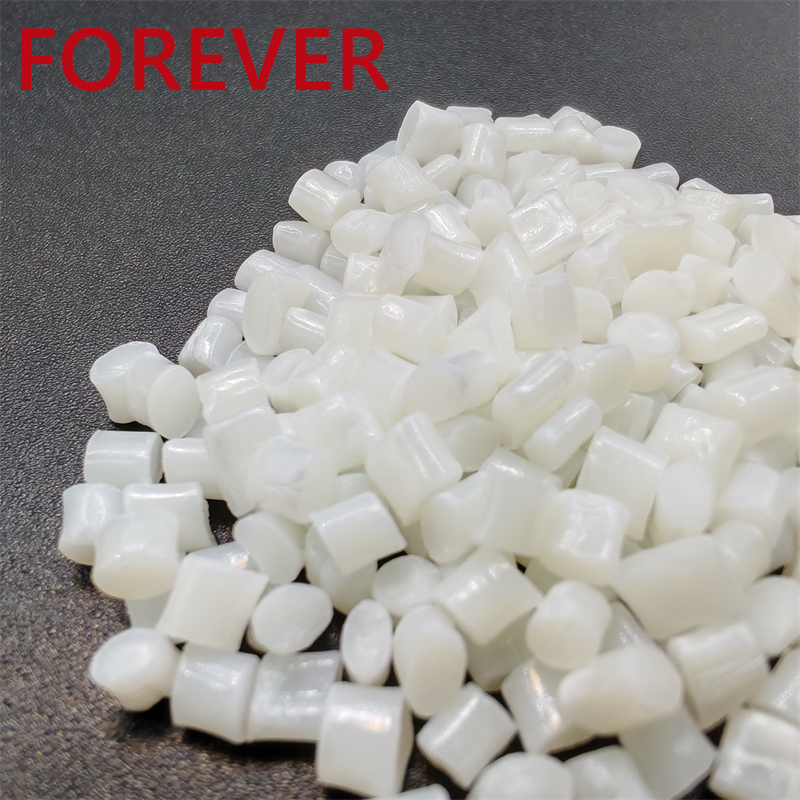

Polyethylene DMDA-8008H

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

DMDA-8008H is mainly used for injection molding high-rigidity and high-strength materials, which is suitable for beverage bottle manufacturing. DMDA-8008H is the HDPE (high-density polyethylene) material produced by Dushan Zihua Petrochemical. It has high rigidity and high-intensity characteristics and is especially suitable for making beverage bottles.

Performance characteristics

DMDA-8008H HDPE has the following performance characteristics:

1.High rigidity: It has excellent rigidity and can withstand high pressure and load.

2.High -intensity: It has high stretching stress and stretching stress, which can withstand a large external force.

3.Excellent physical properties: The melt quality flow rate, density, stretching stress stress, stretching and fracture stress all meet the standards and perform well.

Application field

DMDA-8008H HDPE is mainly used in the following fields:

1. Beverage bottle manufacturing: Due to its high rigidity and high-strength characteristics, DMDA-8008H HDPE performed well in beverage bottle manufacturing, becoming the preferred material 1 of many beverage manufacturers.

2.Other packaging areas: Due to its excellent physical and chemical properties, DMDA-8008H HDPE is also suitable for other packaging areas, such as plastic boxes and injection plastic bottle caps.

Processing advantage

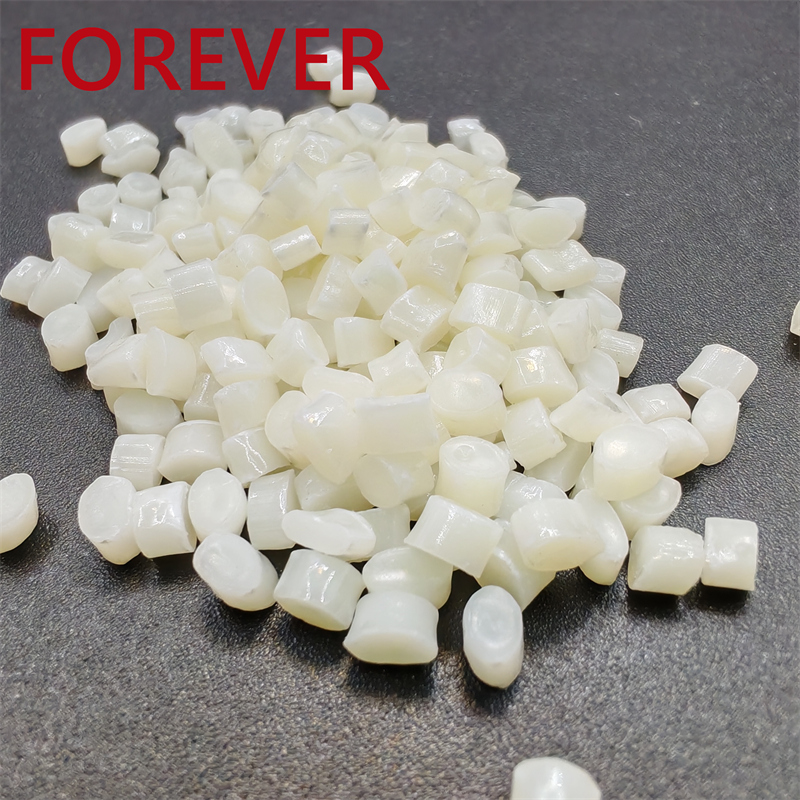

DMDA-8008H HDPE shows the following advantages during processing:

1.Machining performance is good: The melt quality flow rate is moderate and easy to process.

2.The scope of application is wide: suitable for various processing methods such as injection molding, blowing plastic, and suitable for manufacturing various plastic products.

In summary, DMDA-8008H HDPE has performed well in beverage bottles and other packaging fields with its high rigidity and high-intensity characteristics and has a wide range of application prospects.

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts