Maoming Petrochemical Plastic Products

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

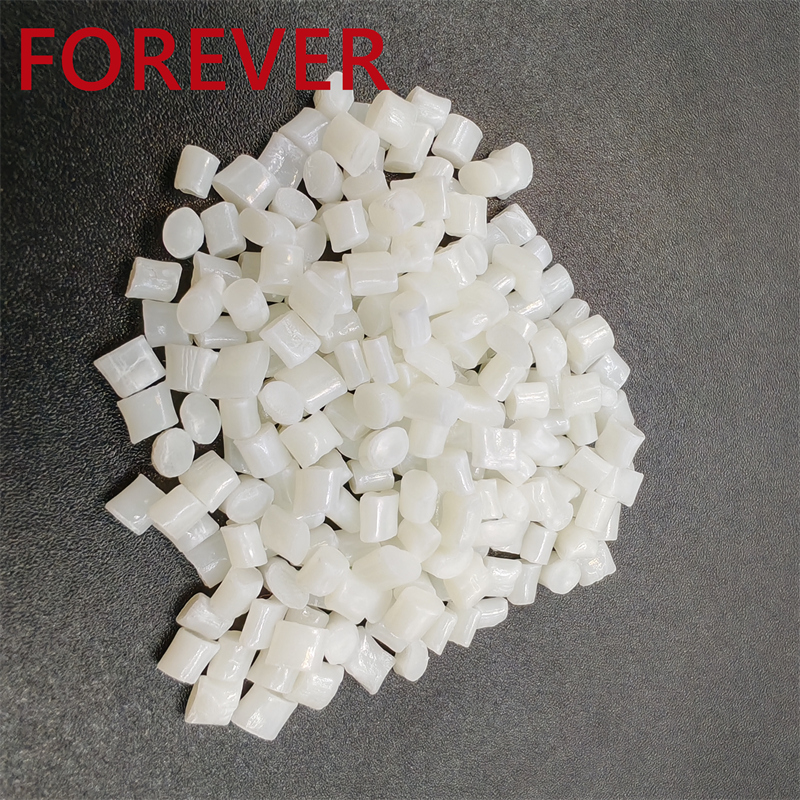

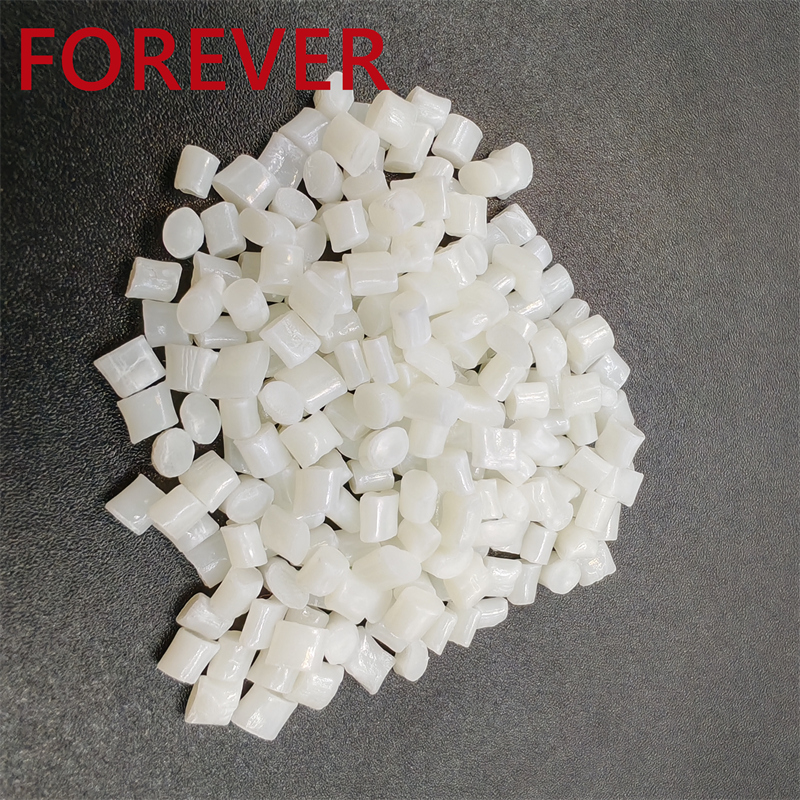

Low density polyethylene (LDPE):

951-050: It is suitable for blowing plastic, extruded film, etc., which is a transparent level.

2400hg: It has injection molding and tough grade performance, high transparency, high strength, high rigidity.

868-000: High melting fingers, good liquidity, can be used for plastic flowers, plastic fans, etc.

2426K: It can be used for injection molding and blowing plastic. It belongs to a transparent and high -temperature -resistant thin -film -level plastic raw material.

Line low -density polyethylene (LLDPE):

M2720A: It is suitable for blowing molding and has chemical resistance.

DNDA-7230: It can be used for injection, blowing film, with high gloss.

High -density polyethylene (HDPE):

TR-168: It can be used for high-intensity extrusion levels, blowing plastic film and plastic bags.

HXM50100: It has high rigidity, heat resistance and cold, suitable for blowing plastic, such as PE high -density polyethylene.

Polypropylene (PP):

T03: It can be used for injection molding, extrusion, blowing plastic, drawing, etc., with a variety of characteristic levels, such as transparent levels, high temperature resistance, aging resistance, high rigidity, etc. The use level includes food grade, automotive components, universal grades.

S1003: It can be used for injection molding and belongs to universal plastic raw materials.

HHP10, HHP6, HHP8: High -flow injection molding grade polyacrylpyle plastic particles.

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts