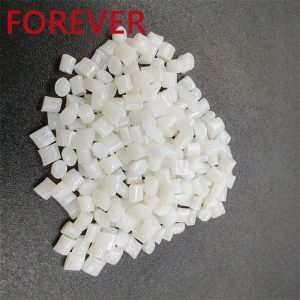

Low-density polyethylene resin LDPE (2100tn00)

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

Low-density polyethylene resin use

Low-density polyethylene resin (LDPE) has a variety of uses, mainly including the following aspects:

1.Plastic bags and packaging materials: The flexibility and toughness of LDPE make it an ideal material for making composite films and plastic bags. Because of its good gas tightness, it is often used in the production of high -quality plastic bags such as food packaging and drug packaging.

2.Plastic seal: LDPE has good flexibility and sealing, so it is often used for plastic, protecting and packaging food, medicines, cosmetics, stationery, etc.

3.Pipeline: The flexibility and corrosion resistance of LDPE make it a mainstream material in pipeline production. It is widely used in tap water, sewer, rainwater pipes, chemical pipelines and other fields.

4.Other uses: LDPE is also used in the fields of agricultural fences, shapes, fabrics and other fields, as well as anti -corrosion and waterproof treatment of metal, concrete, glass fiber reinforcement, wood surface.

characteristic

LDPE is a thermoplastic resin with good flexibility, corrosion resistance and electrical insulation. Its density is between 0.91 g/cm to 0.93 g/cm³, and its liquidity is better and easy to process.

Production process and storage conditions

During the production process of LDPE, pay attention to the control of temperature and pressure to ensure the smooth progress of the aggregate reaction. When storing, keep it in a cool and ventilated place at 5 to 25 ° C, seal packaging to avoid mixing of impurities such as humidity, acid and alkali

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts