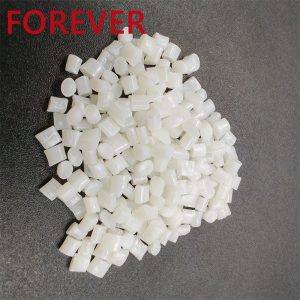

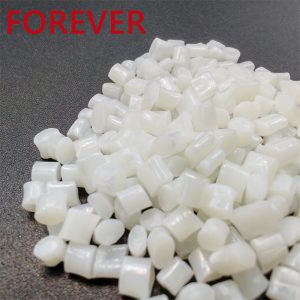

High-density polyethylene film 32st05

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

High-density polyethylene film 32st05 is mainly used for blowing plastic film, which is especially suitable for applications that require high toughness and rigidity balance.

1.Blinding plastic film: 32st05 is the level of polyethylene blowing plastic film. It has excellent processed ability and is suitable for multi-layer thin film manufacturing on extrusion and conversion lines. Conceptual needs.

2.Packaging materials : Due to its non -toxic, odorless, chemical resistance and wear resistance characteristics, 32st05 is also suitable for making various packaging materials, such as food packaging, industrial packaging, etc., which can ensure the safety and completeness of packaging materials.

3.Other applications: Based on its good physical and chemical properties, 32Stest05 may also be used to create other products that require high toughness, abrasion resistance and corrosion resistance, such as mining road panels.

In summary, high -density polyethylene membrane 32st05 is widely used in the fields of blowing film, packaging materials and other fields due to its excellent performance.

Do you want to know what specific application scenarios of high -density polyethylene film 32st05? Such as food packaging, industrial packaging, etc.

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts