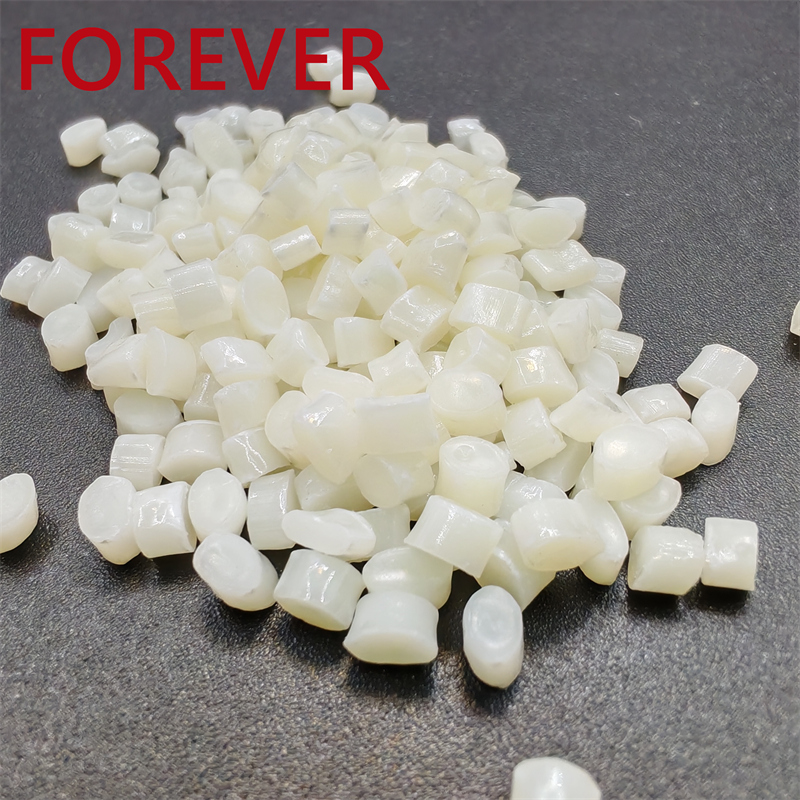

Film M2310

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

Film M2310 is mainly used for thin film applications, especially on occasions that require excellent impact resistance and sealing strength. Specifically:

1.Packaging field: M2310 is suitable for consumption, industry, food or hygienic packaging, such as bags, deep frozen packaging, etc. Its excellent impact resistance can be maintained even at low temperatures to ensure the safety of packaging in transportation and storage.

2.Mixed and common crowding: When mixing and common crowding with linear low -density polyethylene (LLDPE) or low -density polyethylene (LDPE), the M2310 is excellent, suitable for manufacturing a multi -layer composite film to improve the overall performance of the film.

Other applications: Although the main purpose is in the field of thin membranes, according to the use of similar products, the M2310 may also be applicable to the occasions that need to be observed, such as car -ship paint paint, printed circuit board (PCB), etc.

In summary, the film M2310 is widely used in the fields of packaging, mixed and crowding with its excellent performance.

Do you also want to know what information about the film M2310? For example, its performance characteristics, application fields, etc.

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts