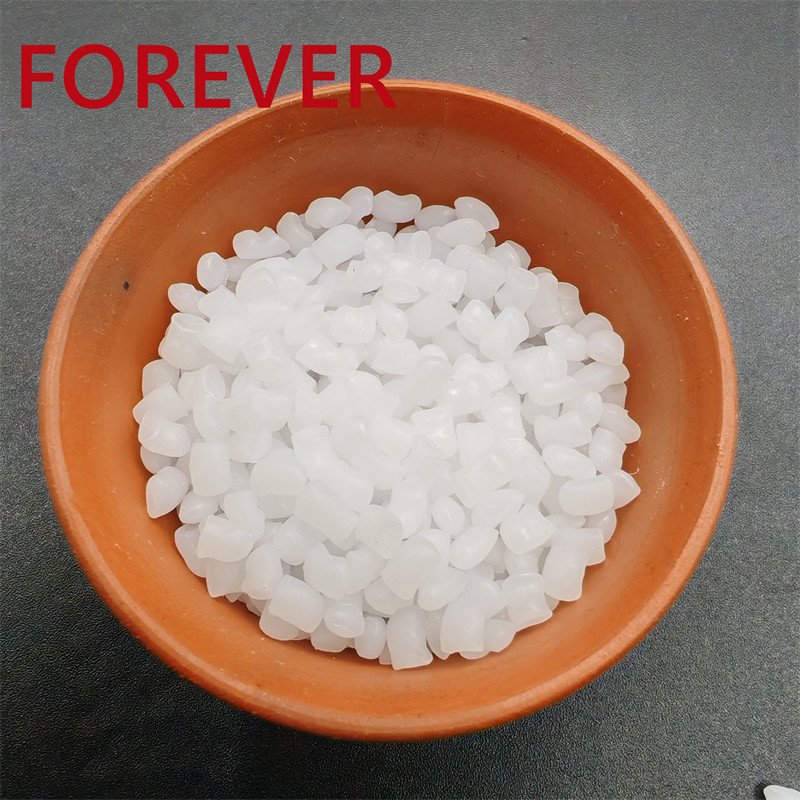

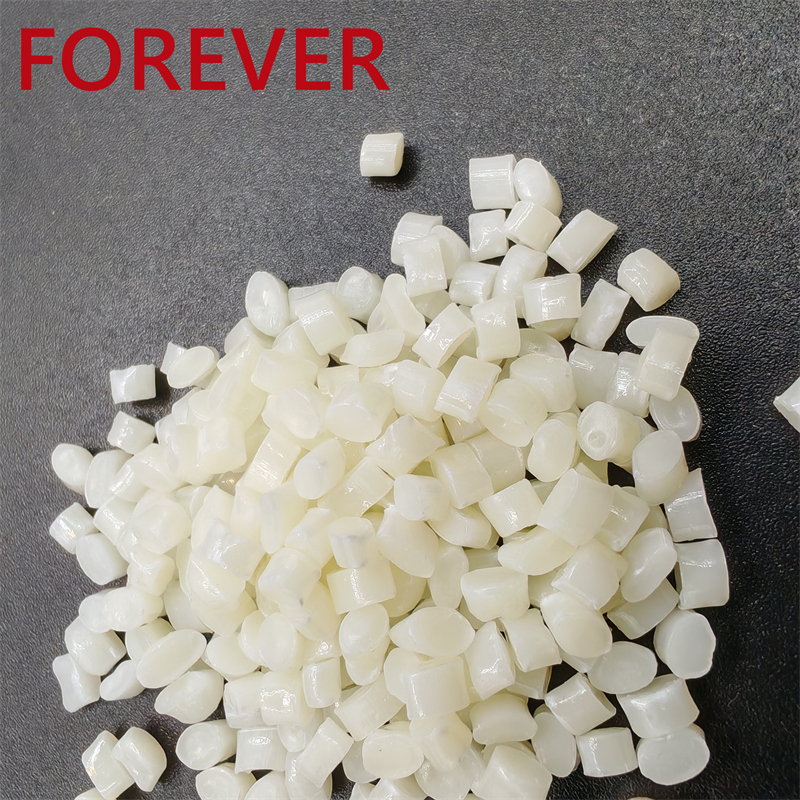

ABS material

Require A Quote

If you have any questions about our products and service,please feel free to leave us a message

In our daily life, ABS materials are everywhere. Its full name is acryline-butadiene-styrene cluster. This material is widely used for its excellent comprehensive performance. But do you know that ABS is not only a darling in industry, it may also be a frequent visitor on your table! Yes, you did not hear it wrong. The ABS material can also become food -grade materials under specific conditions. So, what is ABS material? How does it become a food grade?

ABS is a thermoplastic plastic, which is concentrated by three different monomeryl acryl, butthonne, and styrene. These three monomers each bring the three major characteristics of ABS: acrylite brings hardness and heat resistance, butylene provides toughness and impact resistance, while the styrene is given ABS good processing performance and gloss Essence It is the perfect combination of these three that has made ABS materials in the fields of toys, electronic equipment shells, automotive components and other fields. But when we talk about food -grade ABS, we are concerned about whether it is safely exposed to food.

Food -grade ABS must meet strict food safety standards, which means that it cannot contain substances that are harmful to the human body and will not release harmful substances when they contact food. In China, the standard for plastic materials and products for food contact is jointly formulated by the National Health Commission and the State Administration of Market Supervision. For example, the GB 4806.7-2023 standard specifies the specific requirements of plastic materials and products for food contact, including which ingredients are allowed to be used, and their use limits.

Of course, when producing food -grade ABS, the choice of raw materials is very important. Materials that meet food safety standards must be used. It is necessary to ensure that raw materials do not contain harmful substances, such as heavy metals, plasticizers and other harmful additives.

In the production of food -grade ABS, the use of additives and pigments is particularly limited. If these substances are not used properly, they may become hidden dangers of food safety. Therefore, when choosing these auxiliary materials, manufacturers will strictly screen those types of certified, harmless to the human body. For example, pigments must be food grade and cannot contain heavy metal components, and additives must ensure that they will not migrate to food under the specified temperature and conditions.

Through these strict measures, food -grade ABS can become a material that is safely exposed to food without sacrificing its original physical properties.

FAQs

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts