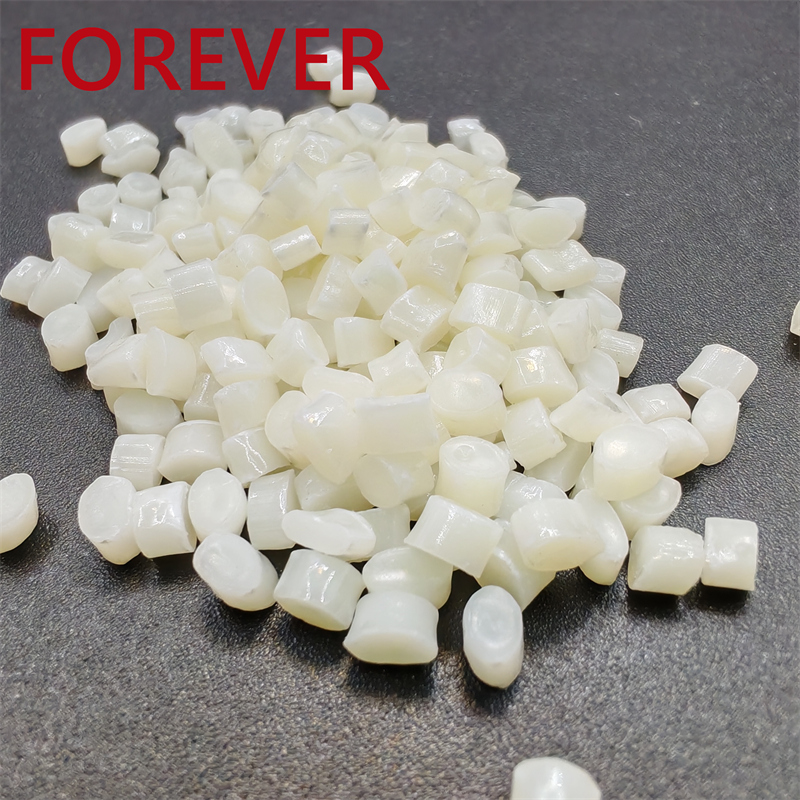

How does Sinopec ensure the quality and consistency of its polypropylene resin? 1

Raw Material Control Strict Supplier Selection: Sinopec carefully selects suppliers of raw materials such as propylene monomer, catalysts, and additives. It establishes strict evaluation and auditing mechanisms for suppliers to ensure that the quality of incoming raw materials meets high standards134. Quality Inspection of Raw Materials: Thorough inspections and…

카테고리:

태그:

견적 요청

당사의 제품과 서비스에 대해 궁금한 사항이 있으시면 언제든지 메시지를 남겨주세요.

Raw Material Control

Production Process Optimization

자주 묻는 질문

네, 우리는 품질을 테스트하고 확인하기 위해 샘플 주문을 환영합니다. 혼합 샘플도 허용됩니다.

샘플은 3~5일이 소요되고, 주문 수량이 많을 경우 대량 생산에는 1~2주가 소요됩니다.

최소 주문 수량, 샘플 확인을 위한 1개 가능

네, 저희는 제품에 대해 1년 보증을 제공합니다. 보증 기간 이후에도 저희는 제품의 애프터 서비스와 예비 부품 교체를 계속 제공할 수 있습니다.