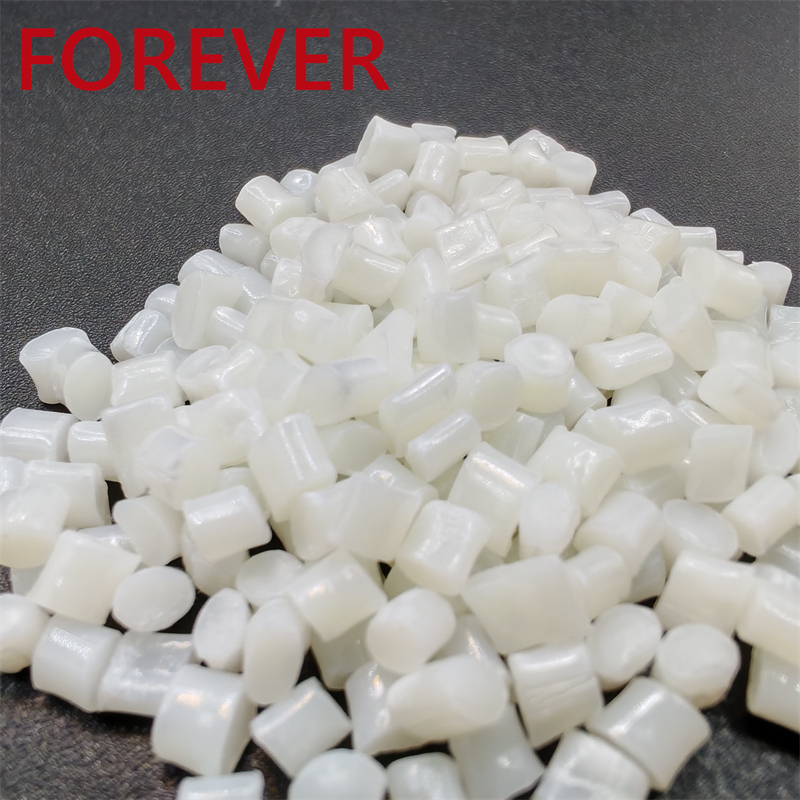

Polyethylene GA450 is a remarkable polyethylene grade renowned for its unique combination of properties that make it highly sought-after in various industries.

1. Physical Properties

GA450 typically exhibits a medium – density range. This density level contributes to its well – balanced physical characteristics. It has a good balance between stiffness and flexibility. The material is not overly rigid, which allows for some degree of bending and shaping without cracking, yet it maintains sufficient stiffness to hold its form, making it suitable for applications where structural integrity is crucial.

2. Processing Advantages

One of the key strengths of Polyethylene GA450 lies in its processing capabilities. It has an optimized melt flow index. This means that during manufacturing processes such as injection molding, blow molding, and extrusion, it can flow smoothly through the dies and molds. This ease of processing not only speeds up production but also reduces the likelihood of defects in the final products. Manufacturers can achieve high – quality, consistent outputs with relative ease.

3. Chemical Resistance

GA450 offers excellent chemical resistance. It can withstand exposure to a wide range of chemicals, including acids, alkalis, and many organic solvents. This property makes it ideal for applications in the packaging of chemical products, as well as in industrial containers and pipes that may come into contact with various substances.

4. Applications

In the packaging industry, GA450 is commonly used for manufacturing bottles, jars, and containers. Its chemical resistance ensures the safe storage of different products, from food and beverages to household chemicals. In the construction sector, it is utilized in the production of pipes for water supply and drainage systems due to its durability and resistance to environmental factors. Additionally, it finds applications in the production of automotive components where its combination of physical properties provides both functionality and longevity.