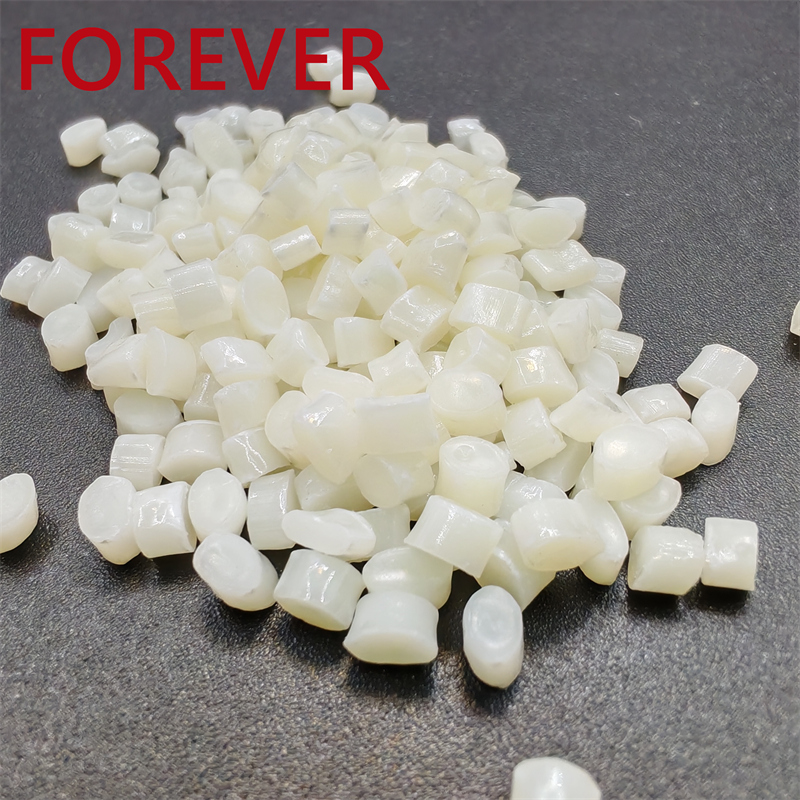

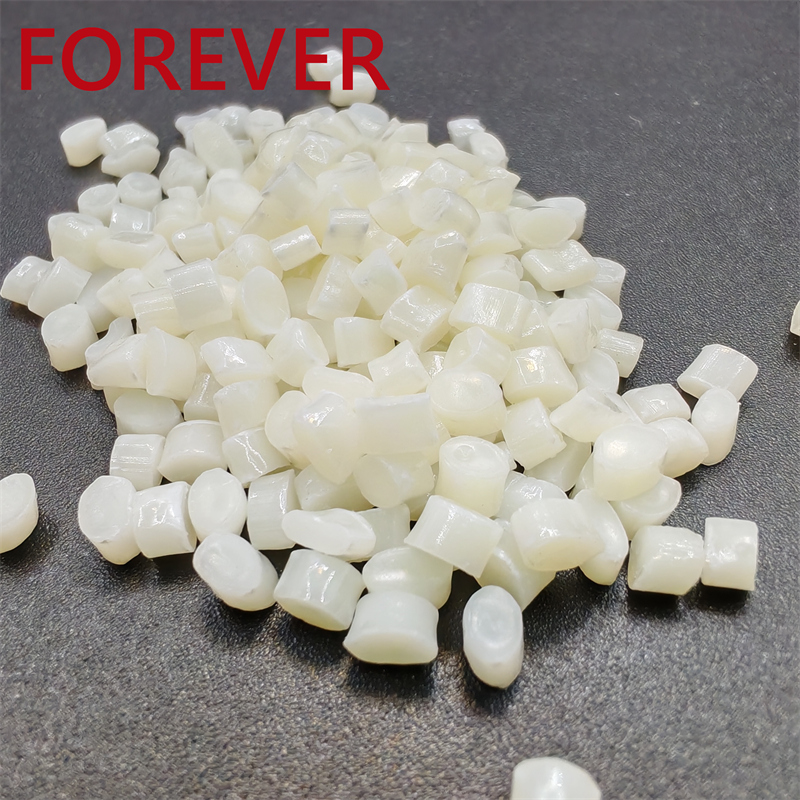

Common modification methods and applications of ABS materials

견적 요청

당사의 제품과 서비스에 대해 궁금한 사항이 있으시면 언제든지 메시지를 남겨주세요.

PC/ABS alloys are to improve ABS flame retardability. They have good mechanical strength, toughness and flame retardability. They are used for building materials, automotive and electronic industries, such as TV, office automation equipment shells and telephone machines. In PC/ ABS alloys, PC contributes heat resistance, toughness, impact strength, strength flame retardability, and ABS advantages are good processability, apparent quality and low density, and focus on automotive industry components.

ABS/PA alloys are impact resistance, chemical resistance, good liquidity and heat -resistant materials. It is used for industrial components such as electric tools, sports appliances, grass cutting machines and snow blowers, and office equipment shells.

ABS/PBT alloys have good heat resistance, strength, chemical resistance and liquidity, suitable for car interior parts, motorcycle pads, etc.

Anti -electrostatic ABS materials The main uses of the permanent antistatic of antistatic agents are: transmission mechanisms such as copy machines, fax machines, etc., videos and advanced audio tapes.

High -gloss ABS is used for home appliances such as vacuum cleaners, electric fans, air -conditioners, telephones and other appliances. Low gloss ABS is used for automotive interior parts such as instrument panels, instruments, pillars, etc. luster.

The flame retardant ABS resin has a good impact strength and surface hardness within a certain temperature range. It has good size stability, a certain chemical resistance, and good electrical insulation. Flame retardant ABS materials are widely used in industrial fields such as mechanical parts, automotive components, electronics, instruments, textiles, and construction.

The heat -resistant ABS material has a good impact strength and surface hardness within a certain temperature range. It has good size stability, excellent chemical resistance and good electrical insulation. It is widely used in the field of automotive components, such as car dashboards, body plates, interior decoration boards, steering wheels, sound insulation boards, door locks, bumpers, ventilation pipes and many other components.

자주 묻는 질문

네, 우리는 품질을 테스트하고 확인하기 위해 샘플 주문을 환영합니다. 혼합 샘플도 허용됩니다.

샘플은 3~5일이 소요되고, 주문 수량이 많을 경우 대량 생산에는 1~2주가 소요됩니다.

최소 주문 수량, 샘플 확인을 위한 1개 가능

네, 저희는 제품에 대해 1년 보증을 제공합니다. 보증 기간 이후에도 저희는 제품의 애프터 서비스와 예비 부품 교체를 계속 제공할 수 있습니다.