How does Sinopec ensure the quality and consistency of its polypropylene resin? 1

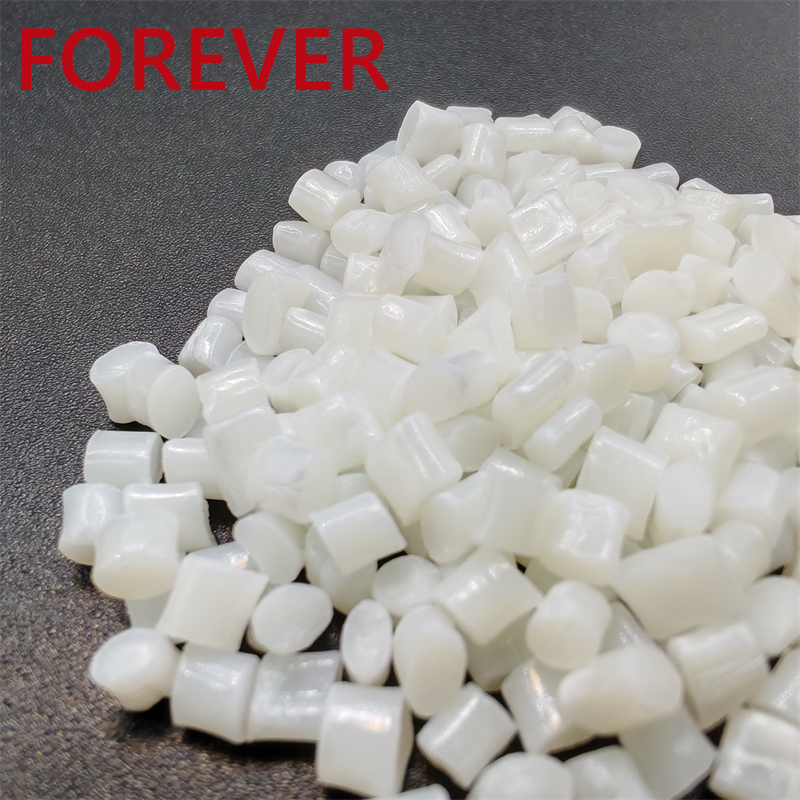

Raw Material Control Strict Supplier Selection: Sinopec carefully selects suppliers of raw materials such as propylene monomer, catalysts, and additives. It establishes strict evaluation and auditing mechanisms for suppliers to ensure that the quality of incoming raw materials meets high standards134. Quality Inspection of Raw Materials: Thorough inspections and…

カテゴリー:

タグ:

見積もりを依頼する

当社の製品やサービスについてご質問がございましたら、お気軽にメッセージをお寄せください。

Raw Material Control

Production Process Optimization

よくある質問

はい、品質のテストと確認のためのサンプル注文を歓迎します。混合サンプルも受け付けます。

サンプルには 3 ~ 5 日かかり、注文数量がこれを超える場合の量産には 1 ~ 2 週間かかります。

最小注文数量は低く、サンプルチェック用に1個からご利用いただけます。

はい、当社製品には1年間の保証が付いています。保証期間後も、製品のアフターサービスやスペアパーツの交換を引き続き提供いたします。