How does Sinopec ensure the quality and consistency of its polypropylene resin? 1

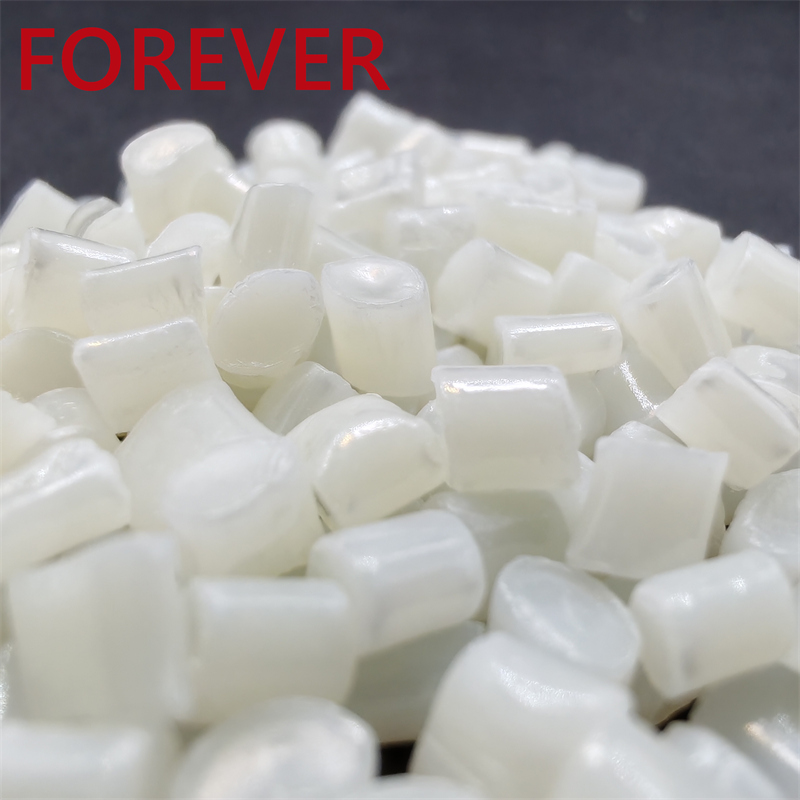

Raw Material Control Strict Supplier Selection: Sinopec carefully selects suppliers of raw materials such as propylene monomer, catalysts, and additives. It establishes strict evaluation and auditing mechanisms for suppliers to ensure that the quality of incoming raw materials meets high standards134. Quality Inspection of Raw Materials: Thorough inspections and…

Categorie:

Etichette:

Richiedi un preventivo

Se hai domande sui nostri prodotti e servizi, non esitare a lasciarci un messaggio

Raw Material Control

Production Process Optimization

Domande frequenti

Sì, accettiamo ordini di campioni per testare e controllare la qualità. Sono accettabili campioni misti.

Per i campioni sono necessari 3-5 giorni, per la produzione in serie occorrono 1-2 settimane per quantità di ordine superiori.

MOQ basso, 1 pz per controllo campione disponibile

Sì, offriamo 1 anno di garanzia sui nostri prodotti. Dopo il periodo di garanzia, possiamo continuare a fornire assistenza post-vendita dei prodotti e sostituzione dei pezzi di ricambio