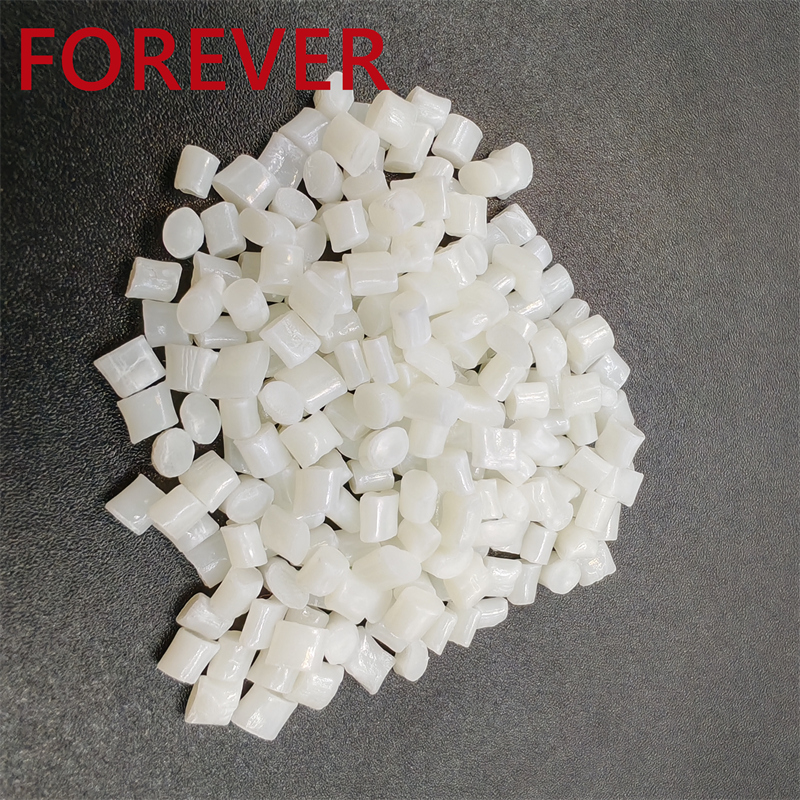

High-density polyethylene film 32st05

Richiedi un preventivo

Se hai domande sui nostri prodotti e servizi, non esitare a lasciarci un messaggio

High-density polyethylene film 32st05 is mainly used for blowing plastic film, which is especially suitable for applications that require high toughness and rigidity balance.

1.Blinding plastic film: 32st05 is the level of polyethylene blowing plastic film. It has excellent processed ability and is suitable for multi-layer thin film manufacturing on extrusion and conversion lines. Conceptual needs.

2.Packaging materials : Due to its non -toxic, odorless, chemical resistance and wear resistance characteristics, 32st05 is also suitable for making various packaging materials, such as food packaging, industrial packaging, etc., which can ensure the safety and completeness of packaging materials.

3.Other applications: Based on its good physical and chemical properties, 32Stest05 may also be used to create other products that require high toughness, abrasion resistance and corrosion resistance, such as mining road panels.

In summary, high -density polyethylene membrane 32st05 is widely used in the fields of blowing film, packaging materials and other fields due to its excellent performance.

Do you want to know what specific application scenarios of high -density polyethylene film 32st05? Such as food packaging, industrial packaging, etc.

Domande frequenti

Sì, accettiamo ordini di campioni per testare e controllare la qualità. Sono accettabili campioni misti.

Per i campioni sono necessari 3-5 giorni, per la produzione in serie occorrono 1-2 settimane per quantità di ordine superiori.

MOQ basso, 1 pz per controllo campione disponibile

Sì, offriamo 1 anno di garanzia sui nostri prodotti. Dopo il periodo di garanzia, possiamo continuare a fornire assistenza post-vendita dei prodotti e sostituzione dei pezzi di ricambio