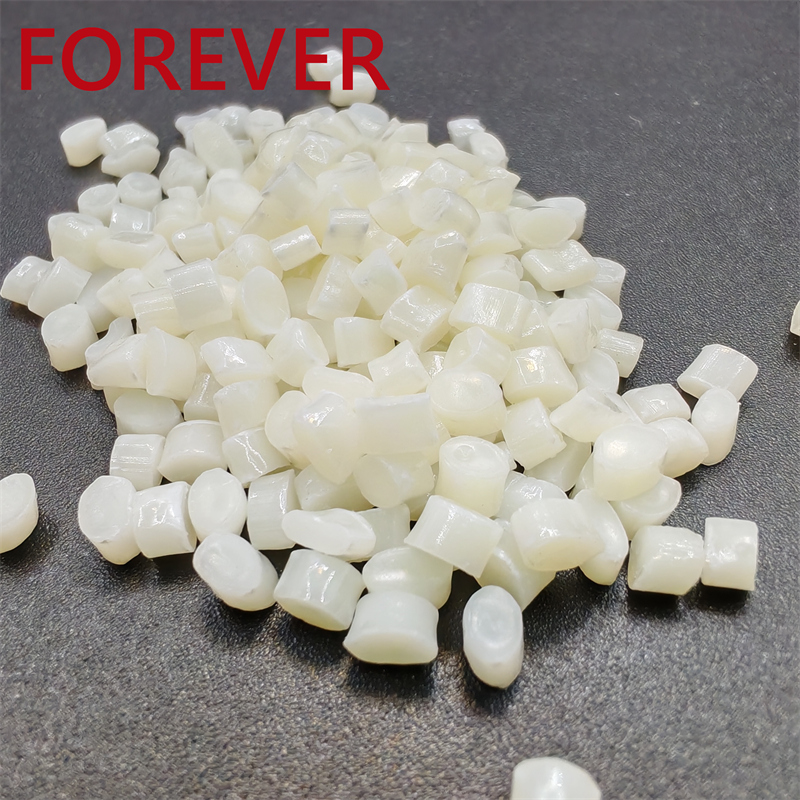

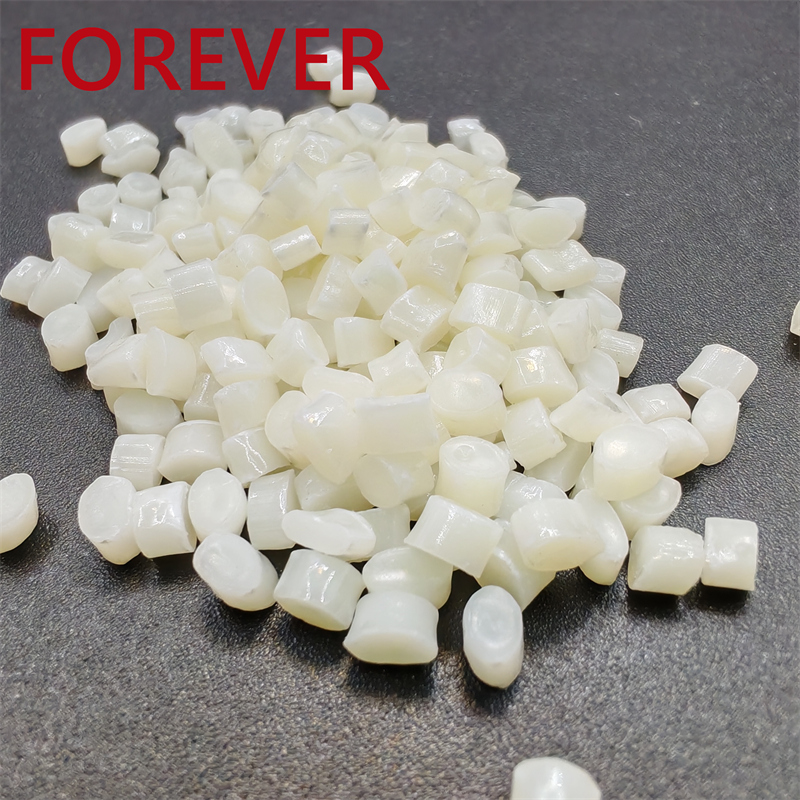

Common modification methods and applications of ABS materials

Richiedi un preventivo

Se hai domande sui nostri prodotti e servizi, non esitare a lasciarci un messaggio

PC/ABS alloys are to improve ABS flame retardability. They have good mechanical strength, toughness and flame retardability. They are used for building materials, automotive and electronic industries, such as TV, office automation equipment shells and telephone machines. In PC/ ABS alloys, PC contributes heat resistance, toughness, impact strength, strength flame retardability, and ABS advantages are good processability, apparent quality and low density, and focus on automotive industry components.

ABS/PA alloys are impact resistance, chemical resistance, good liquidity and heat -resistant materials. It is used for industrial components such as electric tools, sports appliances, grass cutting machines and snow blowers, and office equipment shells.

ABS/PBT alloys have good heat resistance, strength, chemical resistance and liquidity, suitable for car interior parts, motorcycle pads, etc.

Anti -electrostatic ABS materials The main uses of the permanent antistatic of antistatic agents are: transmission mechanisms such as copy machines, fax machines, etc., videos and advanced audio tapes.

High -gloss ABS is used for home appliances such as vacuum cleaners, electric fans, air -conditioners, telephones and other appliances. Low gloss ABS is used for automotive interior parts such as instrument panels, instruments, pillars, etc. luster.

The flame retardant ABS resin has a good impact strength and surface hardness within a certain temperature range. It has good size stability, a certain chemical resistance, and good electrical insulation. Flame retardant ABS materials are widely used in industrial fields such as mechanical parts, automotive components, electronics, instruments, textiles, and construction.

The heat -resistant ABS material has a good impact strength and surface hardness within a certain temperature range. It has good size stability, excellent chemical resistance and good electrical insulation. It is widely used in the field of automotive components, such as car dashboards, body plates, interior decoration boards, steering wheels, sound insulation boards, door locks, bumpers, ventilation pipes and many other components.

Domande frequenti

Sì, accettiamo ordini di campioni per testare e controllare la qualità. Sono accettabili campioni misti.

Per i campioni sono necessari 3-5 giorni, per la produzione in serie occorrono 1-2 settimane per quantità di ordine superiori.

MOQ basso, 1 pz per controllo campione disponibile

Sì, offriamo 1 anno di garanzia sui nostri prodotti. Dopo il periodo di garanzia, possiamo continuare a fornire assistenza post-vendita dei prodotti e sostituzione dei pezzi di ricambio