ABS plastic performance introduction and 3 types of modification methods

Richiedi un preventivo

Se hai domande sui nostri prodotti e servizi, non esitare a lasciarci un messaggio

ABS resin is an acrylic-butadiene-styrene cluster. As one of the plastic varieties with excellent comprehensive performance, ABS is continuously developed on the one hand. On the other hand, through the development and technical modification of new varieties Studies have become the sixth largest engineering plastics, especially through modification, ABS derives more new varieties. It can be mixed with a variety of resins into alloys. There are many types and widely used types. They are the main modified plastics.

ABS physical characteristics

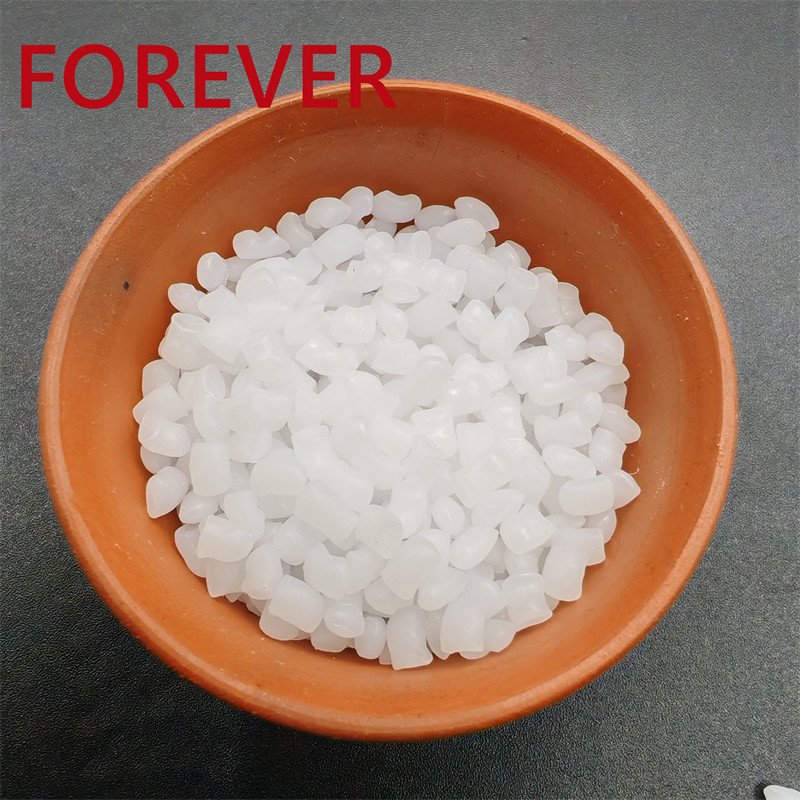

ABS is a light yellow granular or bead -shaped opaque resin. It is non -toxic, odorless, and low water absorption. It has good comprehensive physical and mechanical properties, such as excellent electrical performance, abrasion resistance, size stability, chemical resistance and surface gloss, etc. And easy to process. The disadvantage is weather resistance, poor heat resistance, and flammable.

ABS plastic mechanical performance

ABS has excellent mechanical properties, with excellent impact strength and can be used at extremely low temperatures; ABS has excellent abrasion resistance, good size stability, and oil resistance, which can be used for bearing at medium loads and speed. ABS’s creep resistance is larger than PSF and PC, but smaller than PA and POM. ABS’s curved strength and compression strength are poor in plastic. ABS’s mechanical properties are greatly affected by temperature.

The application range of ABS

High -gloss ABS is used for home appliances such as vacuum cleaners, electric fans, air -conditioners, and telephones. It is achieved by controlling R+(smaller) in controlling ABS. Low luster ABS is used for instrument panels, instrument hoods, pillars and other car interior Pieces, use a thick filler method to make the surface slightly shrink and reduce the surface luster.

The type and characteristics of ABS

Fire fire (flame retardant) level ABSABS is a flammable material and belongs to HB level according to the UL94 standard. ABS burns fast when fire, and a large amount of poisonous gas and black smoke are released, which is not conducive to actual application. With the improvement of science and technology and the improvement of the quality of life, people’s awareness of safety is becoming stronger. Plastic materials used at home and abroad have put forward strict fire -fire burial retardant requirements for plastic materials used in automobiles, buildings, household appliances, and office supplies. Standards and specifications, so the research of flame retardant ABS is of great significance.

There are three main ways to reduce the combustion of ABS resin:

1. Use flame retardant polymers to mix with ABS, such as CPE, PVC;

2. Chemical modification of the existing ABS, such as adding triglycestyrene as ABS for the fourth single system to prepare four components;

3. I want to add flame retardants to ABS through general methods, including inorganic flame retardants (such as MOO3) and organic flame retardants (such as halogen compounds and phosphorus flame retardants). The flame retardant type has an efficient flame retardant effect, but other properties may not be good (such as aging and high cost). Chemical modification ABS requires a specific production process, the process is more complicated. The third method has a balance between cost and performance, and is more flexible in designing multi -functional materials. At present, the flame retardant modification of ABS materials is mainly to add high -efficiency halogen -containing flame retardants.

Heat resistance (high temperature resistance) level ABS

The thermal deformation temperature of heat -resistant ABS resin is generally 90 ~ 105 ° C, which has good heat resistance, toughness and liquidity. It can be used for production of car doors, rear wheels, panels, etc., and is used in the field of home appliances, such as microwave ovens, rice cookers, hair dryers, etc. ABS heat resistance can be increased by reducing the rubber content, increasing SAN molecular weight, and acrylite content, but the use of heat -resistant monomer or heat -resistant aids to develop heat -resistant ABS has attracted more attention from people. Introduce α-methylsthenylene (MS) and Malay anhydride in ABS resin

(MA) and Malayside (mi) can increase the heat resistance of ABS; there are two main ways:

1. MS, MI, etc. are used as the third monomer to converge with the lye, acrylic, and increase the rigidity of the substrate resin and increase its TG. MA and An’s co -concentrations are better than SAN with the same AN content. The vitamin softening temperature is 123 ° C and 103 ° C, respectively. The chemical resistance and physical properties of the two are similar, and the production methods can be universal. MS -based material color is yellow than the ingenal -based material. In actual production, MS only partially replaced the styrene and obtained SMSAN symbol. The replacement ratio depends on the requirements of heat resistance.

2. Add the styrene-Malanic anhydride cluster (SMA) or styrene-Malananamide copolymer (SMI) as a co-mixture component into ABS resin. SMA’s Vichard Softening point temperature can reach 150 ° C. However, SMA is unstable at higher temperatures. It will release carbon dioxide, so it must be released that it is kept enough and can be processed at 260 ° C. Otherwise, the parts will have radiation patterns.

Adding 1%blocked phenol antioxidants and sulfur compactizers to SMA can stabilize it. SMI can be applied in the occasion that requires heat resistance than SMA and MS. The production process of styrene and MI is the same as SAN. SMA and amino or amine reaction and tohomide can also prepare SMI. When SMI is at high temperature, the heat stability is good and does not produce radiation patterns.

Domande frequenti

Sì, accettiamo ordini di campioni per testare e controllare la qualità. Sono accettabili campioni misti.

Per i campioni sono necessari 3-5 giorni, per la produzione in serie occorrono 1-2 settimane per quantità di ordine superiori.

MOQ basso, 1 pz per controllo campione disponibile

Sì, offriamo 1 anno di garanzia sui nostri prodotti. Dopo il periodo di garanzia, possiamo continuare a fornire assistenza post-vendita dei prodotti e sostituzione dei pezzi di ricambio