Five general plastic and common plastic combustion features

Butuh Penawaran

Jika Anda memiliki pertanyaan tentang produk dan layanan kami, jangan ragu untuk meninggalkan pesan kepada kami

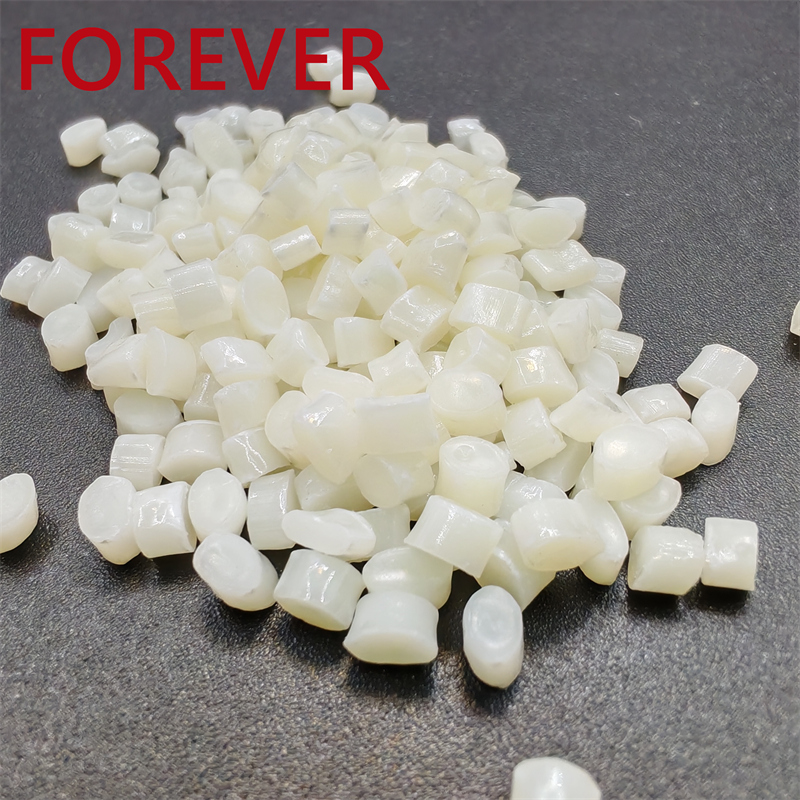

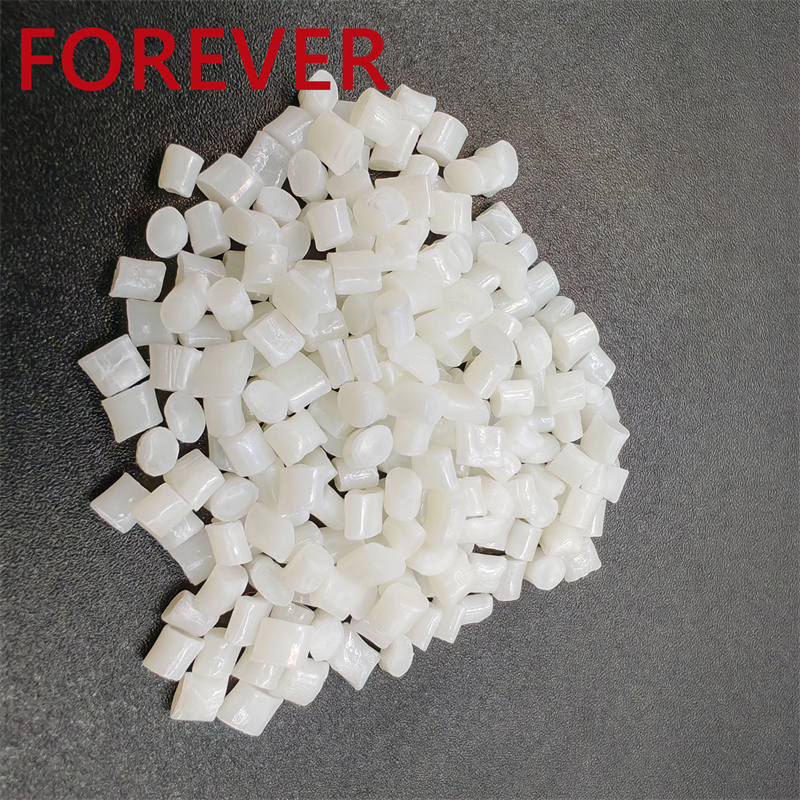

General plastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and acryl-butadylene-lyerene plastic (ABS). These plastics are widely used in various fields such as packaging, building materials, containers, toys.

In addition to these five general plastic, polyethylene dilately glycol (PET) and high -density polyethylene (HDPE) are also common plastic materials in our lives. PET is often used for mineral water bottle and carbonated beverage bottle, while HDPE is common in food packaging bags and cleaning products. The combustion characteristics of these plastics are different. By observing the color, odor and the state of burning, we can make preliminary judgments on the type of plastic. For example, PET is easily softened when burning. The flame is orange and accompanied by a small amount of black smoke, which emit an acidic smell; while HDPE is flammable, the upper end of the flame is yellow, the lower end is blue, and the liquid dripping when burning. The smell when the paraffin is burned.

For example, PET is easily softened when burning. The flame is orange and accompanied by a small amount of black smoke, which emit an acidic smell; while HDPE is flammable, the upper end of the flame is yellow, the lower end is blue, and the liquid dripping when burning. The smell when the paraffin is burned. In the combustion test of plastic such as PVC, PE, PP, PS, and ABS, we also observed their unique phenomena. PVC is rarely used for food packaging that is used to release harmful gases due to the use of toxic additives during the production process and releases harmful gases at high temperatures. Plaza PE, PP and PS are widely used in food packaging and daily life supplies. The combustion characteristics of these plastics are also different. For example, PE is easy to burn and emit paraffin burning odor. When PP is burned, it has a melting dripping and hot oil. PS is easy to burn and release the odor odor. According to the color mother -grain industry network, mastering the basic knowledge and combustion characteristics of these plastics not only helps us use and handle plastic products correctly, but also improve our understanding of plastic products’ safety and environmental protection. In daily life, we should choose appropriate plastic materials based on the purpose and characteristics of plastic products, and properly handle waste plastic products to reduce environmental pollution.

Tanya Jawab Umum

Ya, kami menerima pesanan sampel untuk menguji dan memeriksa kualitas. Sampel campuran dapat diterima.

Sampel memerlukan waktu 3-5 hari, waktu produksi massal memerlukan waktu 1-2 minggu untuk jumlah pesanan lebih dari itu.

MOQ rendah, 1 pc untuk pemeriksaan sampel tersedia

Ya, kami menawarkan garansi 1 tahun untuk produk kami. Setelah masa garansi, kami dapat terus memberikan layanan purna jual produk dan penggantian suku cadang