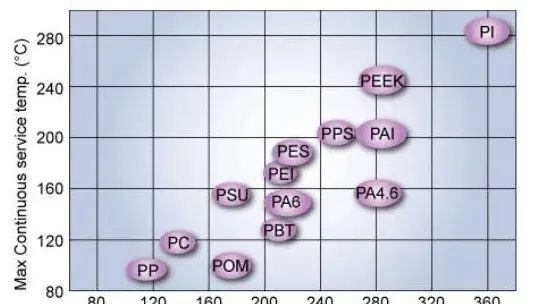

A key factor to consider when choosing a material is its heat resistance.

Generally speaking, if you want to increase the maximum operating temperature of the material,

you need to increase the cost accordingly.

The addition of fillers can greatly increase the hardness and heat distortion temperature of the material.

Moreover, for high-performance and specialized polymers, the addition of glass fiber can significantly reduce the cost.

Because of these, fiberglass-filled polymers are often used as a replacement for metal.

Comparison of maximum operating temperatures and heat distortion temperatures of

glass fiber-filled polymers commonly used to replace metals:

▲ Maximum operating temperature and heat distortion temperature of polymer filled with 30% glass fiber

Adding carbon fiber to high-performance materials can significantly increase the material’s hardness and heat distortion temperature.

Compared with fiberglass filling, carbon fiber filling has the following advantages:

1 Higher hardness

2 Lower density

3 Good electrical conductivity

4 Good friction properties

For these reasons, carbon fiber is often used in automobile fuel delivery lines and fuel systems.