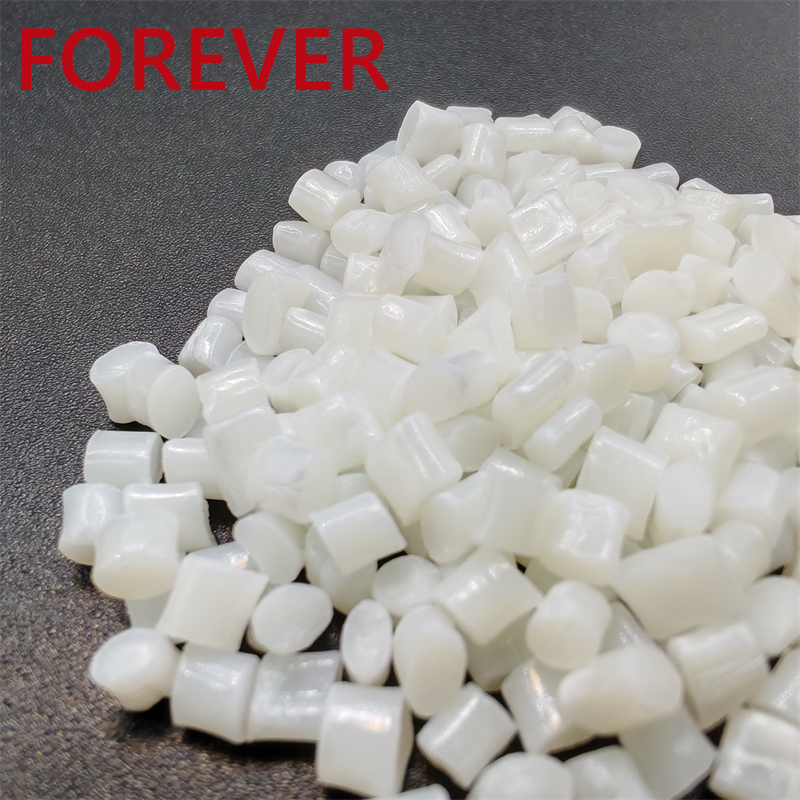

Le développement et l'application des matières premières en plastique ABS et leurs performances d'utilisation

Demander un devis

Si vous avez des questions sur nos produits et services, n'hésitez pas à nous laisser un message

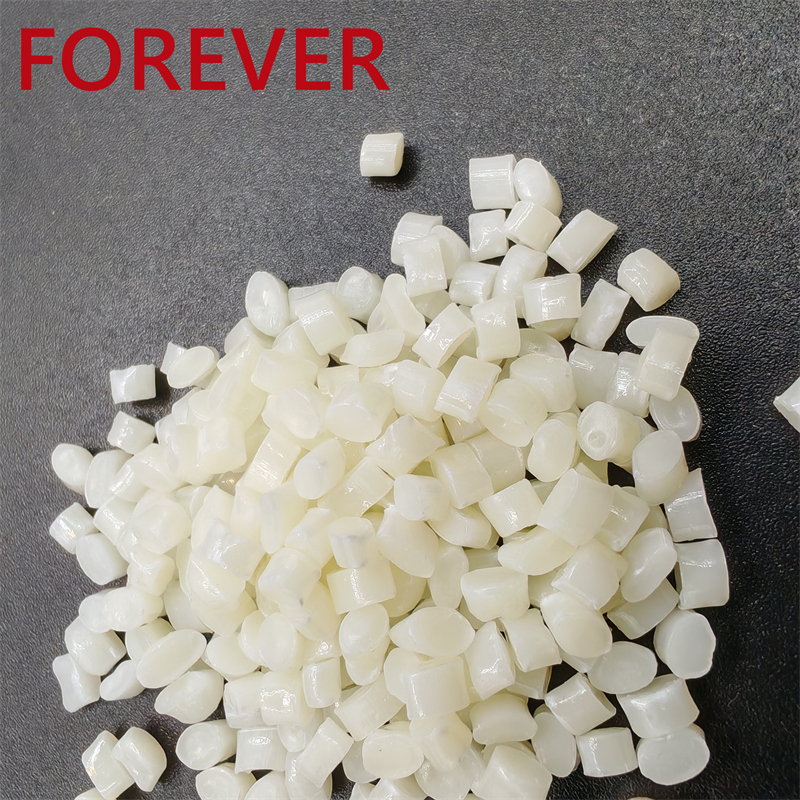

Les avantages de la résine ABS sont la résistance, l'isolation acoustique, la résistance aux rayures, une meilleure résistance à la chaleur et une plus grande beauté que le PP, en particulier dans la résistance horizontale et la température d'utilisation plus stricte. La résine ABS est la troisième résine la plus utilisée, après la polyuréthane et le polypropylène. La résine ABS peut être utilisée pour les petits composants tels que l'intérieur et l'extérieur de la voiture, le volant, le tuyau de guidage d'huile, la poignée et les boutons. L'extérieur de la voiture comprend la calandre avant et l'abat-jour.

La résine ABS est facile à traiter, la stabilité de la taille de traitement et la brillance de la surface sont bonnes, et elle est facile à peindre et à colorer. Vous pouvez également effectuer des performances de traitement secondaire telles que la pulvérisation de métal, la galvanoplastie, le soudage et le collage. Et l'électronique grand public/les appareils électriques, les appareils de bureau comprennent les machines de traitement de données électroniques et le matériel de bureau.

Ces dernières années, sur le marché de l'électronique, la résine ABS maintiendra sa position sur le marché de l'électronique/électronique qui nécessite une résistance ignifuge et élevée à la chaleur. La résine ABS, qui est résistante aux flammes et à la résistance élevée à la chaleur dans la concurrence des alliages plastiques techniques tels que l'ABS/PC, présente des avantages.

La résine ABS a une large gamme d'applications dans le domaine des biens de consommation courante, tels que les tuyaux, plaques ou feuilles de matériaux de construction. Ces dernières années, elle a été remplacée par une résine PVC moins chère. La résine ABS est utilisée dans les domaines liés au bâtiment. Parmi eux, les presses pressées sont utilisées pour les appareils sanitaires tels que les cabines de bain, les revêtements de piscine, etc. En outre, les tuyaux et tuyaux moulés par injection et un petit nombre de conduites de câbles téléphoniques pressés.

L'ABS est un plastique thermoplastique technique universel développé dans les années 1940. C'est une très bonne variété de plastique avec d'excellentes propriétés mécaniques complètes. Il présente non seulement une bonne rigidité, une bonne dureté et une bonne fluidité d'usinage, mais également une grande ténacité.

FAQ

Oui, nous acceptons les commandes d'échantillons pour tester et vérifier la qualité. Les échantillons mixtes sont acceptables.

L'échantillon nécessite 3 à 5 jours, le temps de production en masse nécessite 1 à 2 semaines pour une quantité commandée supérieure à.

Faible MOQ, 1 pièce pour vérification d'échantillon est disponible

Oui, nous offrons une garantie d'un an sur nos produits. Après la période de garantie, nous pouvons continuer à fournir un service après-vente des produits et le remplacement des pièces de rechange.