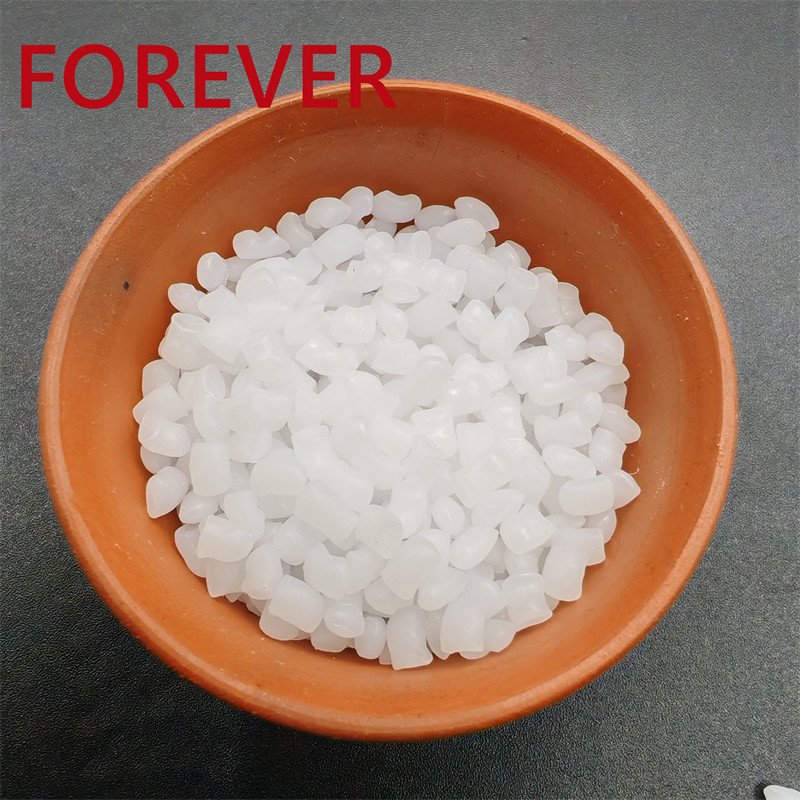

Polyéthylène HP320H

Demander un devis

Si vous avez des questions sur nos produits et services, n'hésitez pas à nous laisser un message

Polyethylene HP320H: A High – Performance Polyethylene Grade

Polyethylene HP320H is a specialized polyethylene variant engineered to meet the demands of diverse industrial applications.

1. Mechanical Properties

HP320H stands out for its high tensile strength. This characteristic enables products made from it to withstand substantial pulling forces without breaking. Coupled with good impact resistance, it can endure sudden shocks and impacts, making it suitable for applications where durability under stress is crucial. Whether it’s in harsh outdoor environments or during transportation, products crafted from HP320H maintain their integrity.

2. Processing Features

This polyethylene grade offers excellent processability. It has a well – defined melt flow rate, which allows for smooth and efficient processing in various manufacturing techniques. In injection molding, it can fill complex molds precisely, ensuring the production of high – quality, detailed parts. During extrusion, the consistent melt flow enables the creation of uniform pipes, films, and sheets. This ease of processing not only improves production efficiency but also reduces production costs.

3. Chemical Resistance

HP320H exhibits remarkable chemical resistance. It can resist the corrosive effects of a wide array of chemicals, including common industrial solvents, acids, and alkalis. This property makes it an ideal choice for applications involving contact with chemicals, such as in chemical storage tanks, pipelines for chemical transportation, and containers for storing chemical products.

4. Application Spectrum

In the packaging industry, HP320H is used to manufacture sturdy and reliable packaging for products that require protection against mechanical stress and chemical exposure. In the construction field, it is employed in the production of durable pipes for plumbing and drainage systems. Additionally, it is utilized in the automotive industry for manufacturing components that need to withstand harsh conditions and chemical spills.

FAQ

Oui, nous acceptons les commandes d'échantillons pour tester et vérifier la qualité. Les échantillons mixtes sont acceptables.

L'échantillon nécessite 3 à 5 jours, le temps de production en masse nécessite 1 à 2 semaines pour une quantité commandée supérieure à.

Faible MOQ, 1 pièce pour vérification d'échantillon est disponible

Oui, nous offrons une garantie d'un an sur nos produits. Après la période de garantie, nous pouvons continuer à fournir un service après-vente des produits et le remplacement des pièces de rechange.