Connaître une matière première plastique : l'ABS

Demander un devis

Si vous avez des questions sur nos produits et services, n'hésitez pas à nous laisser un message

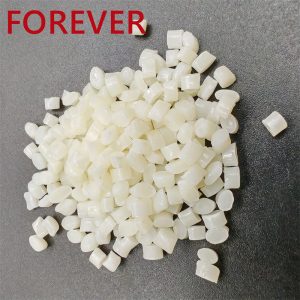

Copolymère acrylonitrile-butadiène-styrène. En raison de la proportion différente des trois monomères, il peut y avoir des performances et des températures de fusion différentes. L'ABS avec des performances de liquidité, s'il est mélangé à d'autres plastiques ou additifs, peut être étendu à l'ABS avec différentes utilisations et performances, telles que les niveaux anti-ruée et résistant à la chaleur. , Niveau ignifuge, niveau transparent, niveau amélioré, niveau de galvanoplastie, etc.

1. Performances générales :

Plastic ABS is non -toxic and tasteless. The appearance is transparent in ivory, or transparent particles or powder. The density is 1.05 ~ 1.18g/㎝3, the shrinkage rate is 0.4%~ 0.9%, the elastic modulus value is 2GPa, the pine ratio is 0.394, the hygroscopicity <1%, the melting temperature is 217 ~ 237 ° C, the thermal decomposition temperature> 250 ℃.

2. Performances mécaniques :

Le plastique ABS présente d'excellentes propriétés mécaniques, une excellente résistance aux chocs et peut être utilisé à des températures extrêmement basses. Le plastique ABS présente une excellente résistance à l'abrasion, une bonne stabilité dimensionnelle et une résistance à l'huile. Il peut être utilisé pour des charges moyennes et des vitesses faibles. Roulement. La résistance au fluage de l'ABS est supérieure à celle du PSF et du PC, mais inférieure à celle du PA et du POM. La résistance à la courbure et à la compression de l'ABS est médiocre dans le plastique, et les propriétés mécaniques de l'ABS sont fortement affectées par la température.

3. Performances mécaniques :

Le plastique ABS présente d'excellentes propriétés mécaniques, une excellente résistance aux chocs et peut être utilisé à des températures extrêmement basses. Le plastique ABS présente une excellente résistance à l'abrasion, une bonne stabilité dimensionnelle et une résistance à l'huile. Il peut être utilisé pour des charges moyennes et des vitesses faibles. Roulement. La résistance au fluage de l'ABS est supérieure à celle du PSF et du PC, mais inférieure à celle du PA et du POM. La résistance à la courbure et à la compression de l'ABS est médiocre dans le plastique, et les propriétés mécaniques de l'ABS sont fortement affectées par la température.

FAQ

Oui, nous acceptons les commandes d'échantillons pour tester et vérifier la qualité. Les échantillons mixtes sont acceptables.

L'échantillon nécessite 3 à 5 jours, le temps de production en masse nécessite 1 à 2 semaines pour une quantité commandée supérieure à.

Faible MOQ, 1 pièce pour vérification d'échantillon est disponible

Oui, nous offrons une garantie d'un an sur nos produits. Après la période de garantie, nous pouvons continuer à fournir un service après-vente des produits et le remplacement des pièces de rechange.